48 x 24 Slatwall Panel for Wall

Category Slatwall Panels

Tags slatwall board, slatwall panel

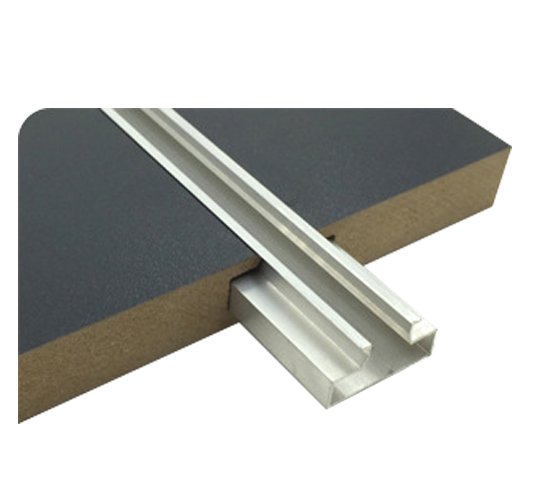

Slatwall panel can be used for a large territory with horizontal strips and vertical strips.

Additional information

| SKU | FWS24FRG |

|---|---|

| Size | 1220*2440*15/18 mm |

| Thickness | 15/18 mm |

| Color | Wood Grain |

| Density | 650 to 750 kgs per CBM |

| Material | MDF |

| Packing | Nude packing or pallet packing |

Procedure of Slatwall Panel

- Chipping

The raw material of MDF is made by separating wood into fibers. Chipping is an important step in the process. It mainly cuts loose wood into wood chips that meet the production specifications to prepare for heat and separate fibers. Provide better conditions - Hot mill

The wood chips cut in the chipping workshop are preheated and cooked, and the fibers are mechanically separated. The quality of the hot grinding process determines the product quality of the MDF. Therefore, the production line with an advanced hot grinder is a necessary condition for improving the quality of the MDF. - Fiber drying

The hot-milled fiber plus sizing makes the fiber moisture content reach 40-50%. If the fiber is not dried, it is difficult to adapt to the subsequent section. In this section, the drying temperature is mainly controlled at about 165°C. , Will not cause the resin to be pre-cured, thereby affecting the mechanical properties of the board such as MOR and IB. - Pavement

The paving process is to store the fibers in the fiber silo for a period of time after drying, and then pass the feeding fan to the paving machine, use the vacuum airflow to realize the rough forming of the fibers, and then use the sweeping roller and the pre-press to realize the forming process of the board failure - Hot press

Hot pressing is an important process in the production of MDF, which plays a decisive role in product quality and output. Under the combined action of heat and pressure, the moisture in the slab vaporizes, evaporates, increases in density, redistributes adhesives and waterproofing agents, and a series of changes occur in each component of the raw material, thereby forming various bonds between the fibers Strength, the process of making products meet and meet quality requirements - Sewage treatment

There is basically no large amount of industrial waste water in the dry production of density board, mainly some cork water extruded by the feed screw. For this kind of wastewater, anaerobic treatment is often used in the general production line, and the process flow chart is as follows: Workshop wastewater -> pre-sedimentation -> water collection sedimentation tank -> anaerobic tank -> air flotation tank -> SBR tank -> Clean pool -> Fiber transition device -> Drain - Melamine Face(Hot pressing and heat dissipation)

This process could Increase the plasticity of the MDF board and promote the compactness of it. 2. Solidify the glue to form a bonding strength. 3. Evaporate water and reduce the moisture content. - Die-cut

This is the final step and put the melamine faced MDF board into die-cut machine and make the slatwall board once in a time, normally the maximum quantity of slots are 15 slots plus 2 half slots.

Slatwall panel system is a durable and simple solution for all kinds of stores from big box to boutique store. It could be much more stronger if reinforced with metal inserts. There are two different strip, namely horizontal strips and vertical strips.

- OEM channels per board

- Wood Grain or solid color available

- Density can be selected from 650 kgs per CBM to 750 kgs

- Compatible with Standard-Sized Accessories

- Suitable for all kinds of metal hooks