Hi there! I’m from Fairwill Display, and today I want to address a question we often encounter: Can I drill through tempered glass? Our clients, especially those involved in custom installations and specialized store fixtures, commonly discuss this topic. Tempered glass, known for its strength and safety features, poses unique challenges when it comes to modifications. As experts in glass showcases and fixtures, we understand the importance of providing clear and detailed information to help you make informed decisions. Let’s dive right into the intricacies of drilling through tempered glass and explore the best practices and alternatives available. In a word, can I drill through tempered glass? The answer is clear: it’s not recommended. Drilling through tempered glass can cause it to shatter due to its internal tension.

Table of Contents

ToggleUnderstanding Tempered Glass

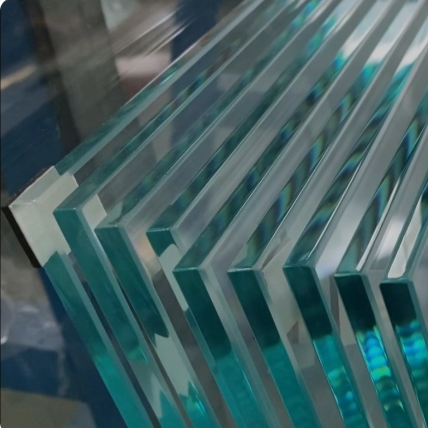

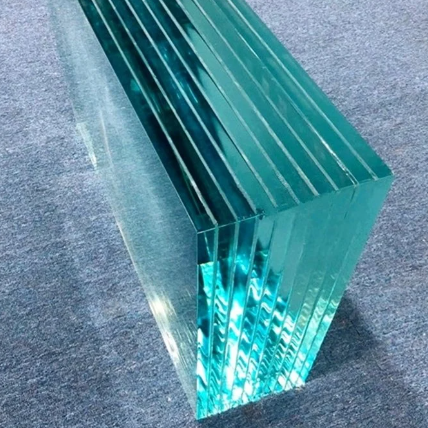

Tempered glass is a type of safety glass. Its strength and durability are well known. The manufacturing process is what sets it apart from standard glass. This process begins with heating the glass. We heat the glass to over 600 degrees Celsius. At this high temperature, the glass becomes very pliable. Once it reaches the desired temperature, the next step is rapid cooling.

We also know rapid cooling as quenching. During quenching, we blow cold air onto the surface of the glass. This cools the surface much faster than the interior. As a result, we create a state of compression on the surface of the glass. At the same time, the interior remains in tension. This combination of surface compression and interior tension is crucial. It gives tempered glass its unique properties.

The process of creating tempered glass is precise and controlled. The heating and cooling must be done evenly. Any imperfections in the glass can lead to failure during quenching. If the cooling is not uniform, the glass can develop weak spots. These weak spots can compromise the strength of the glass. Therefore, high-quality control is essential during manufacturing.

Tempered glass is four to five times stronger than standard glass. This increased strength is due to the compression and tension within the glass. The surface compression makes the glass resistant to impact. When hit, the compression helps distribute the force. This prevents the glass from breaking easily. The tension inside also plays a role. It helps absorb energy, further enhancing the glass’s durability.

Safety is another key feature of tempered glass. Unlike standard glass, which can break into sharp shards, tempered glass shatters differently. When broken, it crumbles into small, blunt pieces. These pieces are less likely to cause injury. This makes tempered glass a popular choice for safety applications. It is used in areas where human impact is a concern.

The use of tempered glass is widespread. Car windows, shower doors, and storefronts often use tempered glass. Its strength and safety features make it ideal for these applications. In the case of car windows, it provides protection during accidents. For shower doors, it ensures safety if the glass breaks.

The heat treatment process of tempered glass is a technological advancement. It enhances the glass’s properties without altering its appearance. The glass remains clear and transparent. This makes it suitable for both functional and aesthetic purposes.

In conclusion, tempered glass is a superior type of safety glass. Its manufacturing process involves heating and rapid cooling. This creates a unique balance of surface compression and interior tension. These properties make it stronger and safer than standard glass. The widespread use of tempered glass is a testament to its effectiveness. Whether for safety or strength, tempered glass is an excellent choice for various applications.

Why Drill Through Tempered Glass?

You might want to drill through tempered glass for several reasons. One common reason is the need to fit the glass into a custom showcase. Custom showcases often require precise dimensions and specific placements for various components. Drilling holes in the glass can be necessary to accommodate shelves, lighting fixtures, or other display elements. This is especially important for businesses that want to create unique and attractive displays.

Another reason for drilling through tempered glass is the installation of the glass in a boutique store. Boutique stores often have unique interior designs that require custom glass installations. This can include glass doors, partitions, or display cases. Drilling holes in the glass allows for the installation of hinges, handles, or other hardware needed to secure the glass in place. This helps in maintaining the aesthetic appeal and functionality of the store’s design.

At Fairwill Display, we understand the need for custom solutions. Our clients come from various industries and have diverse requirements. For example, Ariel in Sweden is one of our valued clients. Ariel runs a boutique store and often requires tailored fixtures for his displays. He needs glass that not only fits his design specifications but also maintains high safety standards.

Ariel’s store has a vibrant and lively atmosphere. To complement this, he often uses tempered glass in his showcases. The tempered glass provides a sleek and modern look, enhancing the overall aesthetic of the store. However, to achieve the perfect fit, drilling holes in the glass is sometimes necessary. This allows for the installation of custom fixtures that align with his design vision.

We have worked with Ariel on several projects. Each project has its unique set of requirements. For instance, one of his recent projects involved creating a custom display case for high-end jewelry. The display case needed to have specific dimensions and include integrated lighting. Drilling holes in the tempered glass was essential to accommodate the lighting fixtures. This ensured that the jewelry was displayed in the best possible light, attracting customers and enhancing sales.

In another project, Ariel wanted to install a glass partition in his store. The partition needed to have a door with handles and hinges. Drilling holes in the tempered glass was necessary to install these components. This provided a functional and aesthetically pleasing solution for dividing the store space.

We understand that drilling through tempered glass can be challenging. We design tempered glass to be strong and safe, making it resistant to drilling. However, with the right tools and techniques, it is possible to achieve the desired results. Our team at Fairwill Display has the expertise and experience to handle such tasks.

The Challenges of Drilling Tempered Glass

Drilling tempered glass is tricky and requires special considerations. Unlike regular glass, tempered glass has unique properties that make it both strong and challenging to work with. One of the key reasons for this difficulty is the internal tension within the glass. This tension is a result of the tempering process, which involves heating the glass to a high temperature and then rapidly cooling it. This process creates a state of compression on the surface and tension inside the glass.

When you attempt to drill into tempered glass, you disturb this delicate balance. The act of drilling introduces localized stress to the glass. This stress can easily overcome the tension inside, leading to the glass shattering. Unlike regular glass, which breaks into sharp, dangerous shards, we design tempered glass to shatter into small, blunt pieces. This is a crucial safety feature that prevents severe injuries, as the blunt pieces are much less likely to cause serious cuts.

However, this safety feature also makes drilling tempered glass particularly challenging. We engineer the glass to shatter under stress to protect users. This means that any attempt to drill requires extreme caution. We use special techniques and tools to minimize the risk of shattering. Standard drill bits and methods used for regular glass or other materials are not suitable for tempered glass.

Professionals use diamond-tipped drill bits when drilling tempered glass. These bits are capable of cutting through the tough surface without causing excessive stress. Additionally, a steady, controlled drilling speed is essential. Drilling too quickly can generate heat and stress, increasing the likelihood of the glass breaking.

The process also requires securing the glass properly. Any movement or vibration can increase the risk of shattering. You must support the glass on a stable surface, often using clamps to hold it in place. This stability ensures that the drilling force is applied evenly, reducing the chances of creating stress points.

Despite these precautions, drilling tempered glass is never completely without risk. Even with the best tools and techniques, the inherent nature of tempered glass means that there is always a possibility of breakage. This is why many professionals recommend considering alternatives to drilling whenever possible.

For instance, if holes or modifications are needed, it is often better to have these done before the glass is tempered. Once the glass undergoes the tempering process, it becomes much more difficult to alter without causing damage. Pre-drilling allows for the necessary modifications while the glass is still in its more malleable state.

Another alternative is to use fixtures that do not require drilling. Clips, clamps, and adhesive solutions can often provide the same functionality without the need to introduce stress to the glass.

In conclusion, drilling tempered glass is a complex and delicate process. The internal tension that makes tempered glass strong also makes it prone to shattering when disturbed. This safety feature, while beneficial in preventing injuries, adds a significant challenge to the drilling process. We need special tools, techniques, and precautions to minimize the risk, but we can never entirely eliminate the possibility of breakage. Whenever possible, consider alternatives such as pre-drilling or using non-invasive fixtures to achieve your desired outcome. At Fairwill Display, we understand these challenges and are here to help you navigate them with expert advice and quality solutions.

Can You Drill Through Tempered Glass?

The straightforward answer is no, you should not drill through tempered glass. Once tempered, the glass cannot be modified without shattering. Any attempt to drill, cut, or grind the glass will inevitably break it. This is due to the unique properties that tempered glass acquires during the tempering process.

The tempering process involves heating the glass to over 600 degrees Celsius. After heating, the glass is rapidly cooled. This rapid cooling process, known as quenching, creates a state of compression on the glass’s surface. Meanwhile, the interior of the glass remains in tension. This combination of surface compression and internal tension makes tempered glass much stronger than regular glass. However, it also makes it incredibly sensitive to stress and pressure points.

When you attempt to drill through tempered glass, you disrupt this delicate balance of compression and tension. The pressure applied by the drill bit creates a stress point that the glass cannot withstand. As a result, the glass will shatter into small, blunt pieces. This shattering is a safety feature designed to prevent serious injuries. Unlike regular glass, which breaks into sharp, dangerous shards, tempered glass crumbles into pieces that are less likely to cause cuts and lacerations.

If you need holes or cuts in tempered glass, you must make these modifications before the tempering process. When the glass is still in its annealed state, you can drill, cut, or grind it without the risk of shattering. This is because the glass has not yet undergone the tempering process and does not have the same internal tensions. Once the modifications are made, the glass can then be tempered to achieve its enhanced strength and safety properties.

Planning is crucial when working with tempered glass. If you anticipate the need for holes or cuts, it is important to incorporate these requirements into the design phase. Communicate your needs clearly to the manufacturer or supplier. This ensures that all necessary modifications are made before the tempering process begins. At Fairwill Display, we offer custom cutting services for our clients. This allows us to provide tempered glass that meets specific design requirements without compromising safety or integrity.

There are various applications where pre-cut holes in tempered glass are essential. For example, custom showcases often require precise placements for shelves, lighting fixtures, or other display elements. These elements need to be securely attached to the glass. Pre-drilling the holes ensures a perfect fit and maintains the glass’s strength. Similarly, in architectural designs, glass partitions, doors, and other structures often require custom modifications. Pre-cut holes allow for the installation of hardware such as hinges, handles, or brackets.

Using tempered glass with pre-cut holes provides several advantages. First, it maintains the glass’s structural integrity and safety features. Second, it ensures that the glass can be securely and effectively integrated into the overall design. Finally, it saves time and reduces the risk of damage during installation.

Alternatives to Drilling

If you need to modify tempered glass, consider these alternatives:

1. Pre-cut Holes: Planning your design ahead of time is crucial when working with tempered glass. Before the glass undergoes the tempering process, you should ensure that all necessary holes are cut. This is because once the glass is tempered, it becomes extremely difficult to modify without causing it to shatter. By having the holes pre-cut, you can avoid the risk of damaging the glass and ensure that it meets your specific requirements.

At Fairwill Display, we understand the importance of precision and customization. That’s why we offer custom cutting services to our clients. We can cut holes in the glass according to your exact specifications, ensuring that the glass fits perfectly into your design. This allows you to achieve a seamless and professional look for your showcases, partitions, or any other glass installations. Our custom cutting services provide you with the flexibility to create unique and tailored glass solutions without compromising on safety or quality.

2. Using Clips and Clamps: Securing tempered glass without drilling is possible with the use of clips and clamps. These devices are designed to hold the glass firmly in place without the need for any holes. They provide a strong and reliable method for attaching glass to various surfaces. Clips and clamps come in a wide range of designs and sizes, allowing you to choose the ones that best fit your specific needs. Whether you are working on a small project or a large installation, there are clips and clamps available to suit your requirements.

3. Adhesive Solutions: High-strength adhesives offer an excellent alternative for bonding tempered glass to other surfaces without the need for drilling. These adhesives are specifically formulated to provide a secure and durable bond, ensuring that the glass stays firmly in place. Using adhesive solutions is a clean method, as it eliminates the need for hardware like screws or bolts. This can be particularly advantageous in creating sleek, seamless designs where visible fixtures might detract from the overall aesthetic. Adhesives come in various formulations to cater to different materials and applications, making them versatile for a range of projects.

Safety Considerations

Safety is paramount when dealing with glass, especially tempered glass. This type of glass, while stronger and safer than regular glass, still requires careful handling to avoid accidents. Always make it a priority to wear protective gear when working with tempered glass. This includes safety goggles to protect your eyes from potential shards and gloves to safeguard your hands from cuts and abrasions.

When handling tempered glass, it is essential to use caution to prevent accidents. The edges of tempered glass can be sharp, and even though it is designed to shatter into small, blunt pieces if broken, the force required to cause such a break can still pose a risk. Always lift the glass carefully, ensuring that you have a firm grip to prevent it from slipping. It is also advisable to use glass suction cups or other handling tools to maintain control and reduce the risk of dropping the glass.

Transporting tempered glass also requires special attention. Ensure that the glass is securely fastened and supported during transport to prevent it from moving or experiencing sudden shocks. Placing the glass on a padded surface and securing it with straps or clamps can help minimize the risk of breakage during transit.

During the installation of tempered glass, ensure that the working area is clean and free of debris. Small particles can cause scratches on the glass surface or create pressure points that might lead to breakage. Additionally, make sure that the glass is properly aligned before securing it in place. Misalignment can create stress points, increasing the risk of the glass shattering under pressure.

Using the appropriate tools is crucial when working with tempered glass. Avoid using tools that are not specifically designed for glass handling or cutting. Using the wrong tools can apply uneven pressure and cause the glass to break unexpectedly. Always follow the manufacturer’s guidelines and recommendations for handling and installing tempered glass.

It is also important to educate anyone who will be handling the glass about the proper safety procedures. Ensure that everyone involved understands the risks and the necessary precautions. Providing training and safety briefings can significantly reduce the likelihood of accidents and injuries.

Case Study: Ariel’s Store in Sweden

Let’s consider Ariel, our typical customer from Sweden. Ariel is lively and passionate about store fixtures, always seeking innovative ways to enhance his boutique’s aesthetics. His boutique, situated in a charming part of Stockholm, attracts a diverse clientele who appreciate both quality and design. Ariel often collaborates with local designers to create unique displays that showcase his products beautifully.

One of Ariel’s recent projects involved revamping his jewelry section. He wanted a display case that not only looked elegant but also provided maximum security for the valuable items. Ariel needed cost-effective, high-quality solutions, and pre-cut tempered glass was the perfect choice. By opting for pre-cut tempered glass, Ariel ensured the display case had precise dimensions and custom placements for integrated lighting. This allowed the jewelry to sparkle brilliantly under the lights, attracting customers’ attention and increasing sales.

Another instance where Ariel benefited from pre-cut tempered glass was when he decided to install a glass partition in his store. This partition needed to have specific cutouts for handles and hinges to create a sleek, modern look. Ariel knew that attempting to drill these holes after the glass was tempered would lead to breakage. Therefore, he worked with Fairwill Display to have all the necessary modifications made before the tempering process. This foresight ensured the glass partition was both functional and aesthetically pleasing.

Ariel’s attention to detail and insistence on high-quality materials paid off. His boutique’s new look received numerous compliments from customers, who appreciated the combination of style and safety. The pre-cut tempered glass not only enhanced the visual appeal of his store but also ensured the safety of both the staff and customers.

Through these examples, it is clear how our products help Ariel achieve stunning displays without compromising on safety. By choosing pre-cut tempered glass, Ariel maintains the high standards of his boutique, ensuring that each installation is both beautiful and secure.

Conclusion

So, can I drill through tempered glass? The answer is clear: it’s not recommended. Drilling through tempered glass can cause it to shatter due to its internal tension. Instead, plan your design with pre-cut glass or use alternative methods like adhesive solutions or clips and clamps. At Fairwill Display, we support our clients with quality products and expert advice. We understand the importance of safety and precision in your projects. Our team provides custom cutting services to ensure that all necessary modifications are made before the glass is tempered. Our goal is to help you create beautiful, safe displays for your business. Whether you need pre-cut holes, custom fixtures, or alternative installation methods, we are here to assist you. With our expertise, you can achieve stunning and secure displays that meet your specific needs.

Final Thoughts

Remember, tempered glass is designed for safety. Its unique properties make it much stronger than regular glass, but also more sensitive to modifications. Any attempt to drill, cut, or grind tempered glass can compromise its integrity, causing it to shatter into small, blunt pieces. This safety feature is intentional, preventing sharp shards that could cause serious injuries. Therefore, it is crucial to plan ahead and choose the best methods for your needs.

Before starting your project, think about all the necessary modifications you may need. If your design requires holes or specific shapes, make sure to make these alterations before the tempering process. Pre-cutting the glass ensures that it retains its strength and safety features once tempered. Working with professionals who understand the intricacies of tempered glass can save you time and prevent costly mistakes.

Additionally, consider alternative methods that do not require drilling or cutting. High-strength adhesives can securely bond tempered glass to other surfaces without compromising its integrity. Clips and clamps can also be used to hold the glass in place without the need for modifications. These methods are not only safe but also maintain the aesthetic quality of the glass.

At Fairwill Display, we understand the importance of safety and precision in your projects. We offer custom cutting services to ensure your tempered glass meets your specific requirements. We handle tempered glass with expertise and can provide expert advice on the best methods for your needs. By planning ahead and choosing the right techniques, you can achieve stunning, safe displays that showcase the beauty and durability of tempered glass. Always prioritize safety and consult with professionals to ensure your project is successful and secure.

Thank you for reading! If you have more questions about tempered glass or our products, contact us anytime. Let’s make your displays stand out with quality and safety.