As a display manufacturer, I get this question often—what type of glass is used for display? My answer is simple: tempered glass. But that’s not all. Let’s explore every angle. What Type of Glass is Used for Display? Tempered glass is the most common type because it’s strong, safe, and clear.

Table of Contents

ToggleUnderstanding Glass Types for Display Fixtures

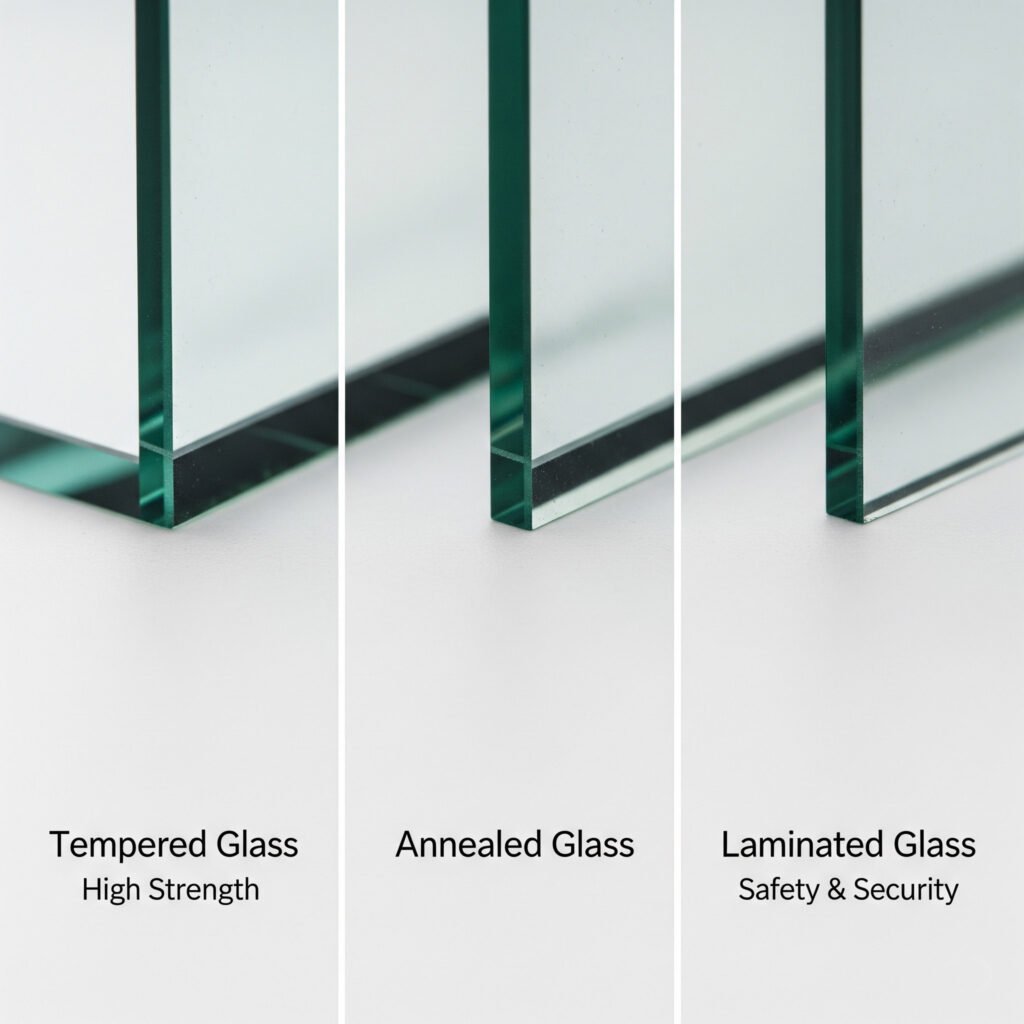

Tempered Glass: Reliable Strength and Broad Use

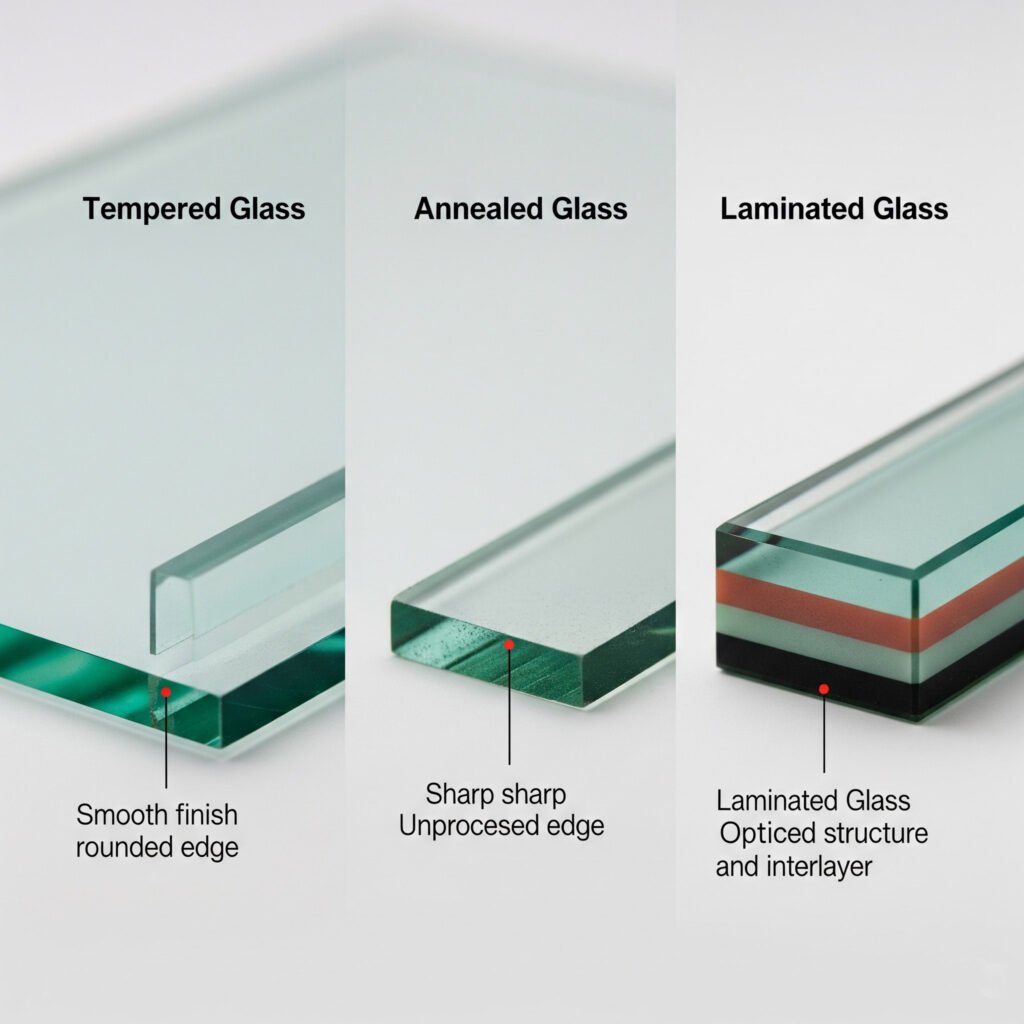

Tempered glass stands out as the most reliable choice for retail displays. It’s been heat-treated to increase strength and resist impact, making it a preferred material for most store fixtures. This glass doesn’t just offer better resistance to physical stress—it also shatters into small, blunt fragments rather than sharp shards when broken. That provides an extra layer of safety that’s crucial in busy retail settings where customers, staff, and children interact with the display units frequently.

Beyond safety, tempered glass also performs well under temperature changes, which can matter for stores with spotlights, fluctuating climate, or high indoor heat. Unlike standard glass, tempered sheets hold their form and appearance in these environments. While not the cheapest material upfront, its durability reduces replacement frequency and lowers the overall cost of ownership.

Many buyers from the USA, Sweden, and Australia prioritize long-term performance over short-term savings, making this material a practical fit for their demands. Thanks to its clarity and strength, tempered glass continues to dominate retail applications, from counters to cabinets.

Annealed Glass: Limited Use with High Risk

Annealed glass represents the base form of flat glass—simple, untreated, and inexpensive. It suits applications where strength and safety are less critical. For display cases, however, it falls short. Despite its low cost, the fragility of annealed glass can become a liability in retail. Even minor bumps may cause cracks or full breakage, leading to safety issues and potential injury. In commercial environments, such damage can cause both downtime and liability risks, which no store operator wants to deal with.

When it breaks, annealed glass forms large, sharp shards. That increases the risk of serious injury, especially in stores where customers can touch or lean on the fixtures. Maintenance and replacement costs also rise, especially when displays need to look flawless every day. In most Fairwill Display projects, annealed glass is avoided entirely or restricted to non-structural decorative panels. Cost-conscious customers sometimes ask about this material, but we usually advise against it unless their use case is highly controlled and low-traffic.

Laminated Glass: Specialty Protection and Targeted Use

Laminated glass consists of two or more layers of glass bonded with a clear interlayer. It’s designed for added security. Even when broken, the pieces remain stuck together, preventing easy access or falling shards. For high-value product displays—like jewelry or premium electronics—this is an ideal solution. The material blocks most UV rays as well, offering protection for light-sensitive merchandise such as cosmetics or antiques.

However, the price and weight of laminated glass make it less suitable for everyday use in standard retail displays. Because the layers add thickness, the overall fixture becomes heavier. That impacts transport costs and can require stronger support structures. For some wholesalers and suppliers, laminated glass can be the right solution for a narrow range of projects, especially where theft prevention or sunlight exposure is a concern.

Frosted and Low-Iron Glass: Visual Effect and Enhanced Presentation

For specific visual effects, frosted and low-iron glass offer unique advantages. Frosted glass diffuses light and adds privacy, which works well in back panels or cabinet doors meant to obscure part of the display. It’s also used to reduce glare or create a soft, high-end aesthetic. Meanwhile, low-iron glass removes the greenish tint found in standard glass. That creates ultra-clear visuals, which are essential for high-end retail displays where product visibility is key.

These specialty types aren’t about strength but about presentation. While both can be tempered or laminated for safety, their role is primarily aesthetic. When clarity or elegance matters, low-iron glass becomes a great option. Frosted surfaces, on the other hand, serve stores that want to create a modern look while also softening the background. They help elevate product perception without being distracting. I often recommend these styles when a client wants to add unique appeal to their displays while maintaining function.

Comparing Performance and Safety

Strength and Impact Resistance

When evaluating what type of glass is used for display, strength plays a critical role. Retail environments are unpredictable. People lean on counters. Staff rearranges heavy items. Accidents happen. That’s why choosing a glass that resists impact is vital. Tempered glass provides four to five times more strength than ordinary annealed glass. It can absorb stress and vibration without cracking. This allows retailers to use it in high-traffic areas with confidence.

Unlike annealed glass, which may fail from a minor bump, tempered glass holds steady. Even with repeated use and moderate weight, it remains intact. That reliability matters, especially in wholesale scenarios where displays must travel long distances and endure setup stress. Laminated glass also offers good impact resistance. However, its layered structure makes it heavier and less flexible for modular systems. While laminated is ideal for anti-theft or security-heavy settings, tempered glass works best for general merchandising strength.

Store owners want products that hold up. Wholesalers want displays that arrive safely after shipping. Tempered glass serves both needs well. Its ability to resist force reduces breakage losses during logistics. That alone gives it an edge. And when I ship cases globally, especially to the USA and Sweden, durability during transport is a top priority.

Breakage Behavior and Injury Risk

Breakage risk is another critical point. It’s not just about if the glass breaks—it’s about how it breaks. Tempered glass shatters into tiny, dull-edged pieces. These are far less likely to cause serious injury. That safety feature makes tempered glass ideal for customer-facing displays. It meets international safety standards, which is especially important in regulated markets like Australia.

In contrast, annealed glass breaks into sharp, jagged shards. These pose a serious risk to staff and customers. Even a light impact can cause a dangerous mess. That makes it unacceptable for most public retail environments. Some low-end suppliers still use it to cut costs, but it’s not worth the risk. Safety should never be compromised.

Laminated glass, on the other hand, holds together when cracked. It uses an internal interlayer that keeps shards from falling apart. This makes it a good choice for ultra-secure spaces. Jewelry stores and luxury boutiques sometimes ask for laminated glass in specific display zones. Still, the added weight and cost limit its wider use. For most fixtures, tempered glass remains the best mix of safety and practicality.

Retailers care about customer experience. A safe shopping space builds trust. No one wants a display accident on their premises. That’s why safety glass is a must, and why tempered glass continues to be the industry standard across display categories.

Long-Term Performance and Stability

Over time, every store fixture faces wear and tear. That’s why it’s essential to choose materials that age well. Tempered glass maintains its structural integrity over years of use. It doesn’t degrade from temperature swings or light pressure. That long-term consistency makes it reliable for both permanent store fixtures and rotating seasonal displays.

Annealed glass degrades faster. With regular use, micro-cracks can form. These lead to larger breaks. That means costly replacements and downtime. Businesses lose time and money when their showcases fail. Replacing broken units also adds to operational headaches. It’s not just about buying cheaper glass—it’s about what that glass costs over time.

Laminated glass holds well but can delaminate if not sealed correctly. Humidity and heat affect the bonding layer. That’s a risk in stores with bright lighting or varying indoor climates. Retailers in Australia, for example, often ask about heat resistance. Tempered glass handles that challenge better.

Retail fixtures must not only survive daily operations—they must look good while doing it. Tempered glass offers both function and form. It keeps displays intact and attractive through years of exposure. For wholesalers who care about product reputation and return rates, that’s a clear win. Choosing the right glass means choosing long-term peace of mind.

Visual Appeal and Clarity

Optical Clarity: Why It Matters in Retail Displays

Clear glass attracts attention. Customers look through it to see the products inside. Any distortion or tint can hurt the shopping experience. That’s why optical clarity plays a major role in display design. Tempered glass offers high transparency. It lets light pass evenly. That keeps items bright and visible. A clean glass surface also makes products look fresh and high-value. In contrast, poor-quality glass often shows bubbles or waves. These flaws break the visual flow.

They reduce product appeal. Retailers need glass that adds value, not distractions. Therefore, I always prioritize glass with minimal visual noise. I choose tempered options that stay clear even under store lighting. Bright spotlights or ceiling LEDs won’t reflect harshly. That keeps attention on the product, not on glare. Plus, quality clear glass works with any store aesthetic—modern, vintage, or boutique.

Anti-Reflective and Tinted Options for Special Effects

Not every store wants completely clear glass. Some prefer tinted panels for mood or branding. Others need anti-reflective surfaces to reduce glare. Both effects serve unique retail purposes. For example, an anti-reflective finish improves focus. It stops light bounce. This works well in tech stores or jewelry counters where lighting is strong. Shoppers see the product directly—without distraction. Tinted glass, on the other hand, changes the tone. A light grey or bronze tint creates warmth.

This suits boutique displays or fashion brands. It adds atmosphere. At Fairwill Display, I offer these customizations. Clients can pick based on their layout and product line. These finishes are applied to tempered glass, keeping safety and strength intact. That way, visual impact doesn’t sacrifice durability. Also, tinting can add privacy while still allowing visibility. Some stores use this for backlit towers or secure showcases. It hides equipment but highlights key items.

Glass Color Consistency and Edge Polish Quality

Details matter. That includes glass color, tone, and edge finishes. Cheap glass often comes with a green tint. It results from the iron content. While some customers don’t notice it, others find it unattractive. I use low-iron tempered glass when color accuracy is essential. This is especially important for stores that focus on lighting design. For instance, beauty stores and galleries want perfect color rendering. A true white product should appear white—not greenish.

That’s where low-iron clarity becomes essential. Polished edges also improve the overall presentation. Sharp or rough edges make the unit feel unfinished. My products include smooth edge polishing on all visible panels. This prevents chips and creates a high-end look. Polishing also reduces cleaning scratches and avoids injury. Every cut glass panel passes through quality checks. If the edge isn’t polished, it won’t leave the factory. These small improvements make a big difference in retail presentation and longevity.

Maintenance and Long-Term Visual Performance

A clean display sells better. That’s why long-term clarity matters. Tempered glass keeps its shine over time. It doesn’t fog, yellow, or degrade like plastics. It resists minor scratches from cleaning cloths or handling. This durability means less need for replacement. Retailers appreciate that. They want low maintenance and long-term performance. Fingerprints and smudges clean off quickly with glass cleaner. The surface remains smooth and consistent. Unlike acrylic, it doesn’t build up static.

That reduces dust attraction, keeping shelves and counters fresh. With proper care, glass looks brand new for years. That’s key for high-traffic stores. I always recommend microfiber cloths and alcohol-based cleaners. These protect the surface without leaving residue. My team also advises clients on regular cleaning schedules. That’s part of our value-added service. We don’t just sell; we support. By choosing tempered glass with strong visual integrity, store owners protect their brand image. They deliver a clean, professional look every day.

Applications in Retail Fixtures

Glass Counters and Showcases

Glass counters play a key role in retail design. They allow clear viewing, promote trust, and enhance product visibility. Most retailers prefer tempered glass for counters due to its strength and clarity. This glass withstands constant use from both staff and customers. Unlike weaker materials, it doesn’t chip or crack easily. Many of my clients use these counters to display jewelry, phones, or collectibles. Their customers lean in, touch surfaces, and rest items on them.

That level of interaction requires dependable materials. Using tempered glass reduces accident risks and gives store owners peace of mind. From my experience, customers return for more when displays look clean and professional.

Not only do counters attract attention, but they also help with brand presentation. Retailers want an organized, modern feel. Glass offers that—especially when paired with minimalist cabinetry. Annealed glass fails in this application. It can shatter under mild pressure. That risk isn’t acceptable in front-facing displays. Safety must always come first in customer zones. Laminated glass provides security but increases cost.

Most buyers don’t need that unless they’re displaying high-value items. For daily commercial counters, tempered glass remains the most effective solution. Its clarity endures. Its surface stays smooth. It delivers value over time without compromising quality.

Another overlooked benefit of tempered glass counters is lighting. When positioned under spotlights or LED strips, the surface reflects and amplifies product brightness. This elevates the presentation. Products feel more luxurious, even when they’re mid-range. Retailers notice this effect quickly. They often report higher engagement around glass counters compared to wood or plastic ones. A simple upgrade in material can transform the entire shopping experience.

Glass Shelves and Racks

Moving beyond counters, glass shelves serve another key function. Retailers use them for vertical displays—especially with slatwall or gridwall systems. Strength is essential here. Items rest entirely on the glass, often without frames. If the material can’t bear weight, damage follows quickly. That’s why tempered glass becomes the standard again. It supports consistent loading and unloading.

Handbags, shoes, ceramics, and electronics all find a safe space on these surfaces. Shelf dimensions vary by store, but the glass must stay stable regardless of size.

Many wholesalers appreciate the flexibility tempered glass provides. It allows them to stock uniform panels that suit various store needs. Whether the retailer is in Australia or Sweden, they receive reliable performance. Annealed glass would create constant complaints and returns. That would hurt both profit and brand image. On the other hand, laminated glass offers strength but makes racks heavier. That complicates shipping and installation.

Shelf clarity also matters. Customers often look upward or downward at shelves. Glare or distortion causes frustration. Tempered glass ensures clean transparency. Retailers often pair it with backlighting or color-contrasting walls to boost visibility. Items seem to float, creating an upscale effect. Many boutiques use this layout for small accessories. Others go big and display entire product lines.

Display Towers and Cabinets

Display towers take visual merchandising to new heights. These tall units often feature multiple glass sides, allowing 360-degree viewing. That means every panel needs to be strong, scratch-resistant, and optically clear. Once again, tempered glass is the top choice. It handles daily customer movement, protects against unintentional bumps, and enhances product focus. Retailers appreciate how these towers let them maximize floor space while still presenting inventory cleanly.

Cabinets, especially lockable ones, require a similar approach. They hold valuables like watches, gadgets, or high-end accessories. Retailers want customers to see the items clearly while protecting them from theft or tampering. Tempered glass allows for that dual function. It supports security without making the case look overly industrial. Compared to laminated glass, tempered glass keeps the look light and refined. It opens up the space visually, which matters in small stores or pop-up kiosks.

Another benefit is maintenance. Towers and cabinets with tempered glass panels are easy to clean. Store staff can wipe them daily without wearing down the surface. Fingerprints, dust, and spills come off without streaking. That keeps the presentation sharp. Retailers value that consistency, especially in competitive markets. With tempered glass, the product—not the case—remains the focus. And that boosts sales.

In summary, whether used in counters, shelves, or tower units, tempered glass leads in retail display applications. Its balance of strength, safety, and style makes it the natural choice. Store owners, wholesalers, and fixture suppliers all benefit from its performance. That’s why Fairwill Display continues to recommend tempered glass in every fixture solution we provide.

Why Fairwill Display

As a store fixture buyer, I know how hard it is to find the right partner. There are too many suppliers who overpromise and underdeliver. But working with Fairwill Display changed everything for me. Here’s why I trust them—and why I think you should too.

Professional Guidance That Simplifies My Choices

From the first inquiry, their team made things easy. I wasn’t sure what glass type or board material to use. They didn’t push products. They asked smart questions. Then, they gave me clear, practical recommendations.

Their advice helped me avoid costly mistakes. For example, I almost chose regular glass for a counter. They explained the safety risks and guided me toward tempered glass. That one decision saved me long-term headaches.

Even when I asked about things like lighting angles or shelving weight, they had answers. They know retail environments, and it shows. I felt supported at every step.

Their English communication is excellent. I never felt confused or left waiting. Every quote, diagram, and delivery update came on time. That kind of transparency builds real trust.

Quality That Matches Global Standards

When I opened the first container, I could tell the difference. The boards were E1 grade—clean, smooth, and eco-friendly. The tempered glass felt thick and secure. No defects. No scratches. Every piece looked exactly like the samples.

I’ve worked with other suppliers who cut corners. Fairwill Display does the opposite. They care about long-term partnerships, not one-time deals. I could tell they checked every fixture before shipping.

They also package carefully. Nothing arrived broken. Even the metal parts were labeled and easy to assemble. That attention to detail saves time and reduces waste. For me, that’s a big win.

Their products don’t just look good—they last. I’ve had units in my store for over a year now. No cracks. No warping. That kind of durability protects my investment and keeps my store looking fresh.

Cost-Effective Without Cutting Corners

As someone who watches every dollar, I appreciate their pricing. Fairwill Display offers real factory-direct value. They don’t add layers of middlemen, so the price stays fair.

But they don’t compete only on cost. Their value comes from getting the right product at the right price. That includes stronger glass, safer boards, and better construction.

They also help me optimize container space. They suggest fixture sizes that fit better in bulk shipments. That lowers my shipping costs and increases my margins.

With Fairwill Display, I don’t feel like I’m gambling on quality to save money. I feel like I’m investing wisely—getting more than I pay for.

Flexible Solutions for My Unique Needs

Not all stores are the same. I needed custom sizes, specific colors, and logo printing. Fairwill Display said yes to everything. They shared CAD drawings, revised designs quickly, and always listened to feedback.

They’re not just manufacturers. They’re partners. I never felt like I had to fit into their system. Instead, they adapted to mine.

They also understand global shipping. From China to Sweden, everything arrived with proper customs paperwork. No delays. No hidden costs. That kind of reliability makes a big difference in my planning.

Even now, they follow up regularly. They ask if I need refills or new ideas. That ongoing support proves they care.

If you’re looking for a supplier who delivers quality, listens to your needs, and helps you grow, Fairwill Display is the answer. I’m not just a customer. I’m a partner. And I think you could be too.

Send them an inquiry. Ask your questions. You’ll see right away why so many of us trust them for display solutions.