When you start thinking about installing shelves, the first thing that comes to mind is often the tools. What are the best tools for installing shelves? It’s crucial to understand that using the right tools not only makes the process faster but also ensures that your shelves are secure and functional. Installing shelves may seem like a simple task, but it requires precision. A little mistake, like misplacing a screw or drilling at the wrong angle, can ruin the entire setup. What Are The Best Tools for Installing Shelves? Discover essential tools for shelf installation in this comprehensive guide.

Table of Contents

ToggleTool #1: Level – A Must-Have for Accuracy

When it comes to installing shelves, accuracy is everything. A shelf that’s not level will look crooked and could cause problems down the line. What are the best tools for installing shelves? One of the most crucial tools you need is a level. A level ensures that the shelf is perfectly horizontal. In this section, I will dive deep into why a level is necessary, how to use it correctly, and the different types available.

Why Accuracy Matters in Shelf Installation

Before I get into the specifics of how a level works, let’s first discuss why accuracy is important. Imagine installing a shelf for books or decorative items. If it’s even slightly off, the shelf will look uneven. Not only is this visually unappealing, but it can also make the shelf less functional. Items placed on the shelf may slide off if the surface isn’t level.

Accuracy also affects the longevity of your shelf. An uneven shelf puts stress on one side more than the other, which could cause it to sag or even break. For these reasons, ensuring your shelf is perfectly level is not optional—it’s a necessity. A level makes sure everything stays aligned, both for aesthetics and durability.

Types of Levels

There are several types of levels available in the market, and each has its own benefits. The three most common types of levels are the traditional spirit level, the laser level, and the digital level. Each one is designed to suit different kinds of projects. But which one is the best for installing shelves?

Spirit Level (Bubble Level)

The spirit level is the most basic type of level. It consists of a long rectangular tool with one or more liquid-filled tubes containing a bubble. These tubes are positioned at different angles—horizontal, vertical, and sometimes even at 45 degrees. The goal is to position the level so the bubble rests in the center of the tube. When the bubble is centered, you know that the surface is level.

The spirit level is affordable and easy to use, making it an excellent choice for basic shelf installations. However, it does require a steady hand to read accurately. Additionally, it may not be as precise as other types for large projects.

Laser Level

A laser level is a step up from the traditional spirit level. Instead of using a bubble, it projects a laser beam across the wall or surface. Laser levels are often self-leveling, which means they automatically adjust to provide an accurate reading. They can project both horizontal and vertical lines, making them ideal for installing multiple shelves or aligning shelves with other fixtures.

Laser levels are highly precise and can cover a larger area than a spirit level. This is particularly helpful when installing long shelves or ensuring multiple shelves are aligned. While more expensive than spirit levels, laser levels provide an unmatched level of accuracy.

Digital Level

The digital level combines the simplicity of the spirit level with the technology of the laser level. It provides digital readings on an LCD, showing the exact degree of tilt. This makes it easy to know exactly how much to adjust your shelf for perfect alignment. Digital levels are perfect for those who want high precision with the ease of a traditional level. They often come with a built-in inclinometer, which is useful for ensuring that the shelf is not only level but also plumb.

How to Use a Level Correctly

Using a level may seem simple, but there are a few techniques to ensure you get the best results. Here’s a step-by-step guide on how to use a level for shelf installation.

Step 1: Mark the Wall

Before using the level, I recommend marking the desired height for your shelf on the wall. Use a pencil to lightly mark where you want the shelf brackets to go. This will serve as a reference point for your level.

Step 2: Position the Level

Now, take your level and place it against the wall where the shelf will go. If you are using a spirit level, make sure the bubble is in the center. If you are using a laser level, align the projected laser line with the marks you made on the wall.

Step 3: Check for Alignment

Take a moment to step back and check the level. If you are using a spirit level, make sure the bubble is centered. With a laser level, ensure that the laser line is straight and aligned with your marks.

Step 4: Adjust as Needed

If the level is off, make the necessary adjustments. This may involve shifting the level or adjusting the position of the shelf. With a laser level, this may be as simple as realigning the laser. It’s crucial to check the level from different angles to ensure complete accuracy.

Step 5: Confirm the Measurements

After ensuring that the shelf is level, double-check the measurements. Make sure that the distance between the shelves (if installing multiple) is consistent. It’s always better to measure twice before you start drilling.

The Benefits of Using a Level-in-Shelf Installation

Now that we understand how to use a level, let’s take a closer look at the advantages of using this tool for shelf installation.

Accuracy

The main benefit of using a level is accuracy. Whether you are installing a single shelf or multiple shelves, a level ensures that each one is perfectly horizontal. This is crucial for both aesthetic and functional reasons. Uneven shelves not only look bad, but they can also be dangerous.

Durability

A level also helps ensure that the shelf lasts longer. When installed properly, a shelf will hold more weight and won’t sag over time. By checking that the shelf is level, you prevent unnecessary stress on the brackets and wall anchors. This contributes to the overall durability of your shelf.

Efficiency

Using a level speeds up the installation process. Without a level, you would have to measure multiple times, check angles, and even redo parts of the installation. A level removes the guesswork, allowing you to complete the job more efficiently.

Versatility

A level is a versatile tool. Not only is it useful for installing shelves, but it can also be used for a wide range of other tasks, including hanging pictures, installing cabinets, or checking other fixtures around the house. Having a reliable level in your toolkit is always a good idea.

Choosing the Right Level for Your Project

Selecting the right level depends on your specific needs and the type of shelf you are installing. For basic shelf installation, a traditional spirit level should be sufficient. It’s affordable and easy to use.

If you are working on larger projects or need to install multiple shelves, I recommend investing in a laser level. It’s particularly helpful for long shelves or aligning multiple shelves with precision. If you want the best of both worlds, consider a digital level. It combines the ease of use of a spirit level with the precision of modern technology.

Maintaining Your Level

To ensure that your level remains accurate, it’s important to maintain it properly. Here are a few tips:

Store It Properly

When not in use, store your level in a safe place. Avoid dropping it or exposing it to extreme temperatures. Storing it in a protective case can help preserve its accuracy.

Clean It Regularly

Regularly clean your level to remove dirt and debris that can affect its accuracy. Use a soft cloth and mild detergent to clean the surface of the level. Be careful not to damage the bubble tubes or digital components.

Calibrate the Level

For laser and digital levels, you may need to calibrate them periodically. Follow the manufacturer’s instructions to ensure the tool remains accurate. A miscalibrated level can lead to incorrect readings, which can ruin your shelf installation.

Conclusion: Why a Level is Essential for Shelf Installation

In conclusion, what are the best tools for installing shelves? A level is one of the most essential tools you can have. It ensures that your shelves are properly aligned, look good, and remain sturdy over time. Whether you choose a simple spirit level, a high-tech laser level, or a digital level, the accuracy it provides is invaluable for a successful installation.

By using a level correctly, you will make your shelf installation easier, faster, and more reliable. Remember, it’s the small details like using a level that lead to professional results. So, invest in a quality level, and you’ll see the difference in your shelf installation projects.

Tool #2: Drill – For Making Holes

A drill is an essential tool when installing shelves. What are the best tools for installing shelves when it comes to drilling? The drill helps you create holes in the wall, allowing you to secure brackets or screws. It’s one of the most versatile tools for any DIY project.

In this section, I will discuss why a drill is important, the different types of drills available, and how to choose the right one for your shelving project.

Why You Need a Drill for Shelf Installation

The drill is necessary for making precise holes in the wall. Whether you’re installing floating shelves, wall-mounted units, or simple shelf brackets, the drill is your go-to tool. Without it, you would struggle to create the space needed for anchors and screws.

For most shelf installations, you will need to drill holes in the wall to place wall anchors or screws. This ensures the shelf can bear weight without falling. A proper drill with the right attachments can make this task quick and easy.

Additionally, drilling helps you control the placement of the shelf. You can adjust the depth and angle of the hole to ensure it fits perfectly with your shelf brackets. Proper hole placement prevents misalignment, which can cause the shelf to be uneven.

Types of Drills

What are the best tools for installing shelves when choosing the right drill? There are several types of drills to consider. Choosing the right one depends on the material you are drilling into and the size of the shelf you are installing.

1. Corded Drill

A corded drill is often the best option for heavy-duty shelf installations. It provides continuous power, which is ideal for larger jobs. These drills are generally more powerful than cordless models, making them suitable for tougher materials like brick or concrete.

Corded drills are excellent for long-shelf installations where you need to drill multiple holes in tough surfaces. However, they can be restrictive due to the cord, so you need to work within a specific range of motion.

2. Cordless Drill

Cordless drills are more portable and offer greater flexibility. What are the best tools for installing shelves if you need freedom of movement? A cordless drill can easily reach hard-to-reach areas and can be used anywhere. They are perfect for lighter-shelf installations, especially in drywall or wood.

Most modern cordless drills come with adjustable speed settings and battery-powered features. This makes them versatile for various projects, including light to medium-duty shelf installations. Cordless drills are generally easier to use for beginner DIYers because they are lightweight and compact.

3. Hammer Drill

If you are installing shelves on masonry, concrete, or brick walls, a hammer drill is the tool you need. A hammer drill combines the functionality of a regular drill with a hammering action that helps break through harder surfaces.

What are the best tools for installing shelves on tougher materials? A hammer drill provides a pounding motion as it drills, making it easier to penetrate solid materials like concrete or brick. If you’re working in an environment where the walls are very hard, the hammer drill will save you time and effort.

4. Impact Driver

An impact driver is similar to a cordless drill but has a higher torque. What are the best tools for installing shelves when you need extra force? Impact drivers are especially useful when driving screws into dense materials. They are ideal for installing heavy-duty shelves that require strong screws or bolts.

While an impact driver can help with drilling, it’s typically used for driving screws rather than drilling holes. If you’re focusing on screws or bolts as part of your shelf installation, this tool can speed up the process.

Choosing the Right Drill Bit

Once you have selected the drill itself, choosing the right drill bit is crucial. Drill bits come in a variety of shapes and sizes, and using the correct one can make all the difference in your installation process.

1. For Wood

If you are installing shelves on wooden walls or using wooden shelves, a standard wood drill bit is what you need. What are the best tools for installing shelves when drilling into wood? These bits are designed to cut through wood smoothly and quickly. For softwood, you can use a basic wood drill bit. For hardwood, a spade bit or auger bit may be necessary to create larger, deeper holes.

Wood drill bits are designed to prevent splitting the wood, ensuring a clean hole. They are also relatively inexpensive and easy to find.

2. For Drywall

Drilling into drywall requires a different kind of bit. What are the best tools for installing shelves when drilling into drywall? You will need a standard drill bit or a specialized drywall bit. Drywall bits have a pointed tip that helps them start the hole precisely, preventing the drill from slipping.

For drywall installations, you’ll often need to use wall anchors or toggle bolts. This is because drywall alone can’t support heavy shelves without proper reinforcement. The drill bit should be sized correctly to fit the anchors you are using.

3. For Concrete or Brick

When drilling into concrete or brick, you need a masonry drill bit. What are the best tools for installing shelves when working with hard surfaces? Masonry bits are designed with a carbide tip that can withstand the hardness of concrete, brick, or stone.

These bits work best with hammer drills, as the pounding motion of the hammer drill helps the masonry bit break through the tough surface. Always ensure that the drill bit matches the size of the anchors you plan to use.

4. For Metal

If your shelves involve metal brackets or components, you’ll need a metal drill bit. What are the best tools for installing shelves with metal parts? Metal drill bits are made of high-speed steel or cobalt and are designed to drill through metals without damaging the material. Be sure to choose the correct bit size for your screws.

How to Use a Drill for Shelf Installation

Now that you know the types of drills and bits, it’s time to talk about how to use them effectively. What are the best tools for installing shelves when it comes to drill usage? Let’s break down the steps to ensure the installation is done correctly.

Step 1: Measure and Mark the Wall

Before you even pick up the drill, it’s essential to measure and mark where you want the holes. Use a measuring tape to determine the correct height and placement for your shelf. Mark these spots lightly with a pencil.

A common mistake is not measuring properly, leading to uneven shelf placements. Always measure twice to avoid errors. Once the marks are made, double-check their alignment using a level.

Step 2: Choose the Right Drill Bit

Select the right drill bit based on the material you’re drilling into, as discussed earlier. A wood drill bit for wooden walls, a masonry bit for concrete or brick, and a drywall bit for drywall. Choose a bit size that fits the screws or wall anchors you are using.

Step 3: Start Drilling Slowly

Position the drill bit on your mark and start drilling slowly. Do not apply too much pressure at first. Start with a slow speed and gradually increase the speed as the drill bit penetrates the material.

When drilling into hard surfaces like concrete, you may need to use a hammer drill. Keep the drill steady to avoid any slipping. If you’re using a cordless drill, ensure the battery is fully charged before starting.

Step 4: Clean the Hole

After drilling, you should clean the hole to remove any dust or debris. This will make it easier to insert anchors or screws and help the installation process go smoothly. You can use a small brush or a vacuum to clean out the dust.

Conclusion: Using a Drill Effectively

In conclusion, what are the best tools for installing shelves when it comes to drilling? The drill is an essential tool for creating precise holes that are necessary for shelf installation. Whether you’re using a corded, cordless, or hammer drill, it’s important to choose the right drill for your material and purpose.

Remember to measure carefully, select the right drill bit, and drill slowly for the best results. A good drill makes the shelf installation process easier, faster, and more secure. By following the steps outlined above, you can ensure your shelves are installed properly and stay strong over time.

Tool #3: Screws and Wall Anchors – Keep It Secure

When installing shelves, screws and wall anchors play a crucial role in ensuring the stability and safety of the installation. Without the right screws and anchors, your shelves could fail, causing damage to your wall and loss of the items on the shelf. It’s important to choose these components carefully, as they directly impact the durability of your shelving system. In this section, we’ll delve into the different types of screws and wall anchors you can use, and how to select the best ones for your project.

Why You Need Strong Screws and Wall Anchors

The main reason for using screws and wall anchors is simple: they help secure your shelves to the wall. Why are screws and anchors necessary? Walls are made of various materials, each with its strength and stability. Using the wrong hardware for a particular wall can lead to an insecure installation.

Screws are responsible for holding the shelf brackets to the wall. Without screws, the brackets wouldn’t stay in place. Wall anchors are essential when you’re working with materials that are too soft or too thin, like drywall. They help distribute the weight of the shelf and the items on it, preventing the screws from pulling out. What happens if you skip this step? If you don’t use anchors, your screws may not hold, leading to a dangerous situation where the shelf can fall off the wall.

Understanding Different Types of Screws

There are various types of screws available for shelf installations, each designed for specific materials and purposes. Which screws should you use for installing shelves? Let’s look at some of the most common options.

Wood Screws

Wood screws are designed specifically for use on wooden surfaces. They have a pointed tip that makes it easier to penetrate wood without cracking it. Should you use wood screws for drywall? While they are excellent for wooden surfaces, they are not suitable for drywall or plaster. If you’re installing shelves on wooden studs, wood screws are a solid choice. They come in various lengths and thicknesses, so make sure to choose screws that match the size of your brackets and the weight they will hold.

Drywall Screws

For drywall installations, drywall screws are the go-to choice. These screws are designed to hold firmly in drywall, which is softer than wood or concrete. Why choose drywall screws? Their threads are closer together, providing better grip and stability. They also have a sharp point, allowing them to pierce drywall easily. However, drywall screws alone won’t be enough to secure heavy shelves. You need to pair them with wall anchors to ensure they stay in place.

Machine Screws

Machine screws are used for metal surfaces or when you need to attach brackets to metal studs. When should you use machine screws? If your shelving unit is being installed in a metal frame or on a steel stud, machine screws are necessary. These screws are typically smaller in diameter than wood screws but are designed to provide a stronghold in metal.

Self-Tapping Screws

Self-tapping screws are a great option for those who are not using wall anchors. Why are self-tapping screws useful? These screws are equipped with a sharp tip that allows them to tap their hole as they go into the material. This makes them particularly effective for softer materials like wood or plastic. They save time and effort because you don’t need to pre-drill a hole before inserting them.

Types of Wall Anchors

Wall anchors are designed to provide extra stability when screwing into drywall or other soft materials. Without anchors, screws may not hold, especially if the shelf is heavy. What are the best types of wall anchors for shelf installations? There are several types of anchors to choose from, each suited for different situations.

Plastic Expansion Anchors

Plastic expansion anchors are the most common type of wall anchors used for light-duty applications. Are plastic anchors reliable? These are inexpensive and easy to install, making them a good choice for small shelves or lightweight items. When you insert the screw into the plastic anchor, it expands, gripping the surrounding wall material. However, they are not suitable for very heavy shelves.

Metal Anchors

Metal anchors provide more strength and stability compared to plastic ones. When should you use metal anchors? If your shelf is heavier, metal anchors are a better choice. They offer stronger resistance to the weight of the shelf and prevent the screws from pulling out. Some metal anchors are designed for use in hollow walls, where the wall has space between the drywall and the studs.

Toggle Bolts

Toggle bolts are one of the strongest types of wall anchors. How do toggle bolts work? These anchors consist of a bolt and a pair of wings that expand once the bolt is inserted into the wall. This mechanism helps distribute the weight of the shelf across a wider area of the wall, making toggle bolts ideal for heavy-duty shelving applications. They work best in hollow walls or when there is no stud behind the drywall to secure the shelf.

Molly Bolts

Molly bolts are a good choice for drywall installations. What makes Molly Bolts different? When installed, molly bolts expand behind the drywall to create a stronghold. They are particularly useful when you cannot locate a stud behind the wall. Molly bolts can support heavier shelves compared to plastic anchors, making them a reliable choice for medium-duty applications.

Concrete Anchors

If you are installing shelves on a concrete or brick wall, you will need concrete anchors. Why are concrete anchors necessary? These anchors are designed to hold securely in masonry and concrete. They are typically used with a hammer drill to create the necessary hole for the anchor. Concrete anchors are available in various forms, including expansion anchors and sleeve anchors, and are designed to hold heavy loads.

How to Choose the Right Screws and Anchors

Selecting the correct screws and wall anchors depends on several factors. What do you need to consider when choosing screws and anchors? Let’s look at the most important considerations.

Wall Material

The first thing to consider is the material of your wall. If you are installing shelves on drywall, you will need drywall screws and anchors. If your wall is made of wood or concrete, you will need to choose screws and anchors designed for those materials. How do you identify wall material? You can typically identify the material by tapping the wall. If it sounds hollow, it is likely drywall. If it sounds solid, it may be wood or concrete.

Weight of the Shelf

The weight of the shelf and the items you plan to store on it also affects the type of screws and anchors you should use. How heavy is your shelf? Lighter shelves can usually be secured with basic screws and plastic anchors. For heavier shelves, you will need stronger screws and anchors, such as metal anchors or toggle bolts. Always overestimate the weight capacity to ensure the shelf can hold the items safely.

Length and Size of the Screws

It’s important to choose screws that are long enough to penetrate the wall material and anchor securely, but not too long to go through the other side of the wall. How long should your screws be? For drywall, screws should be about 1 ¼ inches long. For wood studs, longer screws may be necessary to ensure a strong hold. Choose screws with a thickness that fits your bracket’s holes.

Installation Tips for Using Screws and Wall Anchors

Proper installation of screws and wall anchors is just as important as selecting the right ones. How should you install screws and anchors? Here are some tips to ensure a secure installation:

Mark the Placement of the Brackets

Before drilling or inserting any screws, mark the spots where your shelf brackets will go. Why is marking important? Accurate marks will ensure that your shelf is level and properly aligned. Use a pencil or chalk to mark the spot, then double-check the measurements.

Drill Pilot Holes

For wall anchors, you need to drill pilot holes before inserting the anchors. How do you drill pilot holes? Use a drill bit that matches the size of the anchor you are using. Make sure to drill the hole straight and at the correct depth to ensure the anchor fits snugly.

Insert the Wall Anchors

After drilling the pilot holes, insert the wall anchors into the holes. How do you insert anchors? Gently tap the anchors into place using a hammer, if necessary. Be careful not to damage the wall as you insert the anchors.

Insert the Screws

Finally, insert the screws into the wall anchors. How do you tighten screws? Use a screwdriver or drill to tighten the screws. Make sure the screws are tight, but be cautious not to overtighten, as this can damage the wall or the anchor.

Conclusion: Secure Your Shelves with the Right Hardware

In conclusion, choosing the right screws and wall anchors is essential to secure your shelves properly. What are the best screws and anchors for installing shelves? The answer depends on your wall material, the weight of your shelf, and the type of installation. By understanding the different types of screws and anchors available, you can select the best ones for your project, ensuring a safe and durable shelf installation.

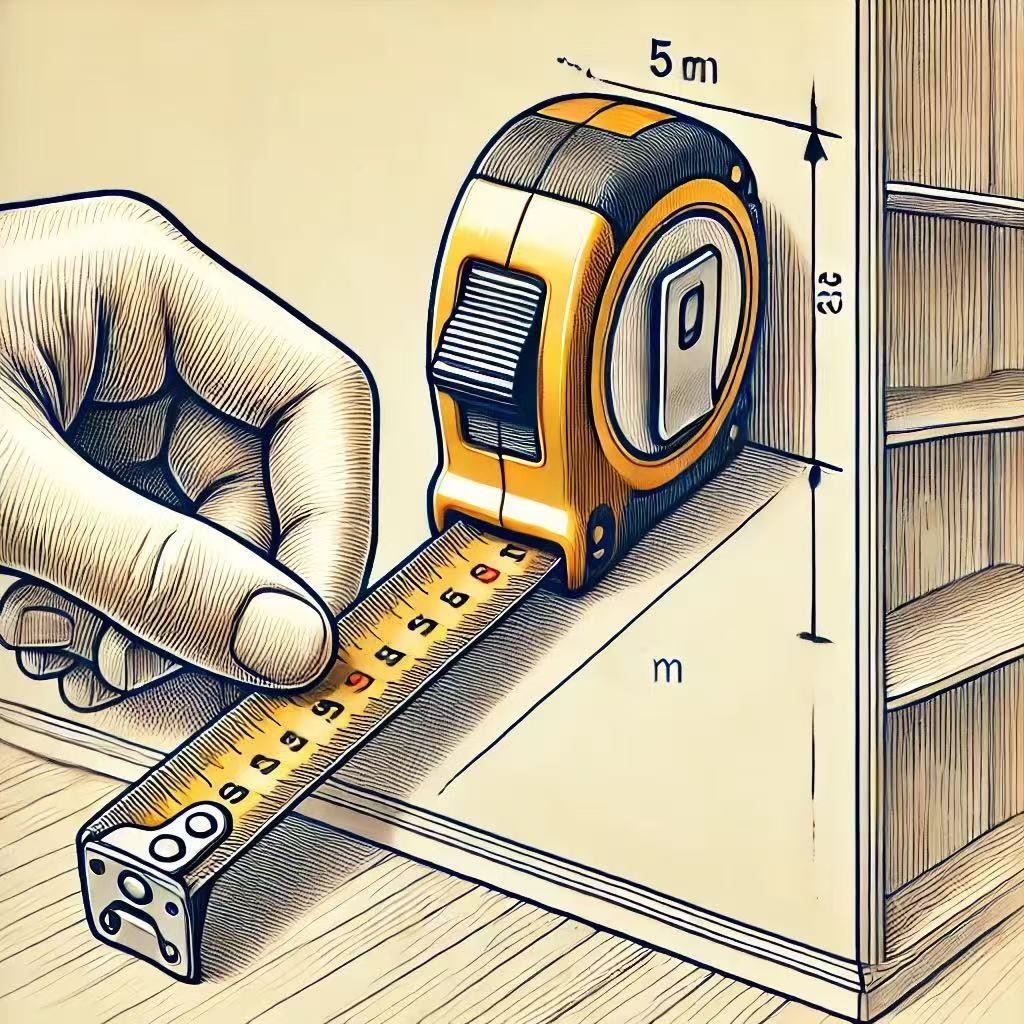

Tool #4: Measuring Tape – For Precision

A measuring tape is one of the simplest but most important tools when it comes to installing shelves. It is often the first tool you’ll reach for before you even start drilling. What are the best tools for installing shelves? The measuring tape allows you to measure everything with accuracy, ensuring that your shelves are placed in the perfect position. In this section, we’ll dive deep into why a measuring tape is indispensable and how to use it effectively during the installation process.

Why the Measuring Tape Matters

You may be asking, why is a measuring tape so important for installing shelves? The answer is simple: accuracy. Without the right measurements, you could end up with shelves that are uneven, crooked, or too high or low. This not only ruins the aesthetic of your space but can also cause the shelf to fail under the weight it was not properly designed to support.

What are the best tools for installing shelves when it comes to precise measurements? A measuring tape gives you a way to ensure your shelves will be level and well-placed. Whether you’re mounting floating shelves, bracketed shelves, or any other style, accurate measurements guarantee that the final result is both functional and visually appealing.

Key Features of a Good Measuring Tape

When choosing a measuring tape for shelf installation, it’s important to look for some key features. The first is length. Most measuring tapes come in lengths ranging from 10 feet to 25 feet. For standard shelf installations, a 10-foot tape is usually sufficient. However, if you’re planning to install larger, more expansive shelves, a longer measuring tape may be more appropriate.

The material of the measuring tape is also important. Metal tape is durable and can withstand the wear and tear of frequent use. On the other hand, fabric tape is lighter and may be easier to handle for smaller projects. While both materials can serve you well, it’s important to choose a tape that feels comfortable in your hand.

Another important feature to consider is the locking mechanism. Many modern measuring tapes come with a locking feature that allows you to keep the tape extended without it retracting. This is particularly useful when you need to take a precise measurement over a long distance. The locking mechanism keeps the tape in place, so you can mark the spot accurately without the tape snapping back.

How to Use a Measuring Tape for Shelf Installation

Now that we know why the measuring tape is essential, let’s talk about how to use it properly for shelf installation. First, measure the area where you want to install your shelf. This is where the measuring tape comes in. Place one end of the tape at the point where you want the shelf to start. Extend the tape to the desired length and make sure you’re measuring in a straight line.

What are the best tools for installing shelves when it comes to measuring vertical space? To ensure that your shelf is placed at the right height, you’ll need to take vertical measurements as well. Start by measuring from the floor to where the shelf will be mounted. If you’re installing multiple shelves, be sure to measure the distance between them to maintain consistency across your installation.

Measuring for Level Shelves

One of the most important things to remember when using a measuring tape is leveling. Shelves that are not level will look crooked and may fail to support the weight of your items. To ensure that your shelf is perfectly level, you’ll need to use the measuring tape in conjunction with a spirit level or laser level.

Measure the distance from the floor to the desired shelf height at both ends. Make sure both measurements are the same. Then, use the level to check that the marks align horizontally. If the marks are off, adjust them accordingly to create a level line for your shelf brackets.

What are the best tools for installing shelves to help with leveling? If you’re installing multiple shelves, it’s critical to ensure each shelf is level with the one below it. After you have measured and marked the location for the first shelf, check that the second shelf’s measurements are consistent. By using the measuring tape and level together, you can achieve perfect horizontal alignment for each shelf.

Adjusting for Obstacles

In many homes or offices, walls are not perfectly straight. It’s common to encounter obstacles such as pipes, vents, or existing furniture that may interfere with the space where you want to install your shelves. The measuring tape is the perfect tool for adjusting your measurements accordingly.

Measure the distance between your shelves and any obstacles, ensuring that the shelf will fit properly. If there are irregularities in the wall, you can adjust the placement of the shelf so that it doesn’t interfere with any structures. This can often mean adjusting the vertical height or moving the shelf slightly to one side.

What are the best tools for installing shelves to overcome such challenges? In cases of irregular walls, a flexible measuring tape is a great tool. Flexible tapes can curve around obstacles or irregularities and give you an accurate measurement of space.

Using the Measuring Tape for Accurate Shelf Placement

Once you’ve measured the height and distance for your shelf, the next step is marking the wall. What are the best tools for installing shelves when it comes to marking your measurements? After getting accurate measurements with your tape, use a pencil to mark the wall at the correct points. This will serve as your guide when you install your brackets or other shelf hardware.

When you place the measuring tape against the wall, be sure to keep it taut to prevent sagging, which can distort the measurement. It’s essential to take multiple measurements at various points along the wall. This ensures that your shelf is placed consistently and accurately.

Common Mistakes to Avoid

Even with a measuring tape, it’s easy to make mistakes when installing shelves. Some of the most common mistakes include misreading measurements or taking measurements from the wrong points. Be sure to double-check your numbers before you start drilling. Even a small mistake can lead to an uneven shelf installation.

Also, it’s easy to get distracted and forget to check for level. Always take the extra time to measure and confirm that everything is perfectly aligned before securing any brackets. Even if you are working quickly, accuracy should be your priority.

Tips for Using a Measuring Tape Effectively

Here are a few tips to make the most of your measuring tape:

Measure twice, cut once: This adage is especially true for shelf installations. It’s always better to take extra time to double-check your measurements than to have to redo the work later.

Use the right units: Depending on where you live, your measuring tape might display measurements in either inches or centimeters. Be sure to use the correct units for your project to avoid confusion.

Mark as you go: As you take measurements, mark your spots with a pencil. This will help you stay organized and ensure your shelf is placed exactly where you want it.

Keep the tape taut: When extending the tape, avoid letting it sag. A sagging tape can result in inaccurate measurements, especially over longer distances.

Use a level with the tape: Always use a spirit or laser level alongside your tape measure to ensure your measurements are both accurate and level.

Conclusion

In conclusion, what are the best tools for installing shelves when you want precision? The measuring tape is an absolute necessity. With its ability to ensure accuracy in every step of the process, the measuring tape guarantees that your shelf installation will go smoothly. By using the measuring tape correctly, you can avoid common mistakes and ensure that your shelves are placed exactly where you want them.

With proper measurements, your shelves will not only look great but will be more stable and functional. So, always prioritize accuracy and don’t rush the measuring process. The time you spend getting it right will pay off in the long run with a beautiful, level shelf installation.

Tool #5: Screwdriver – For Tightening

When it comes to installing shelves, a screwdriver is one of the most crucial tools. What are the best tools for installing shelves when considering the tightening aspect? You can use either a manual or electric screwdriver, depending on the size of your project. In this section, I will dive deeper into why a screwdriver is so essential, how to choose the right one, and some tips for using it effectively.

The Role of a Screwdriver in Shelf Installation

A screwdriver is necessary for tightening screws into place, securing your shelf brackets to the wall. It is not enough to simply drill a hole and insert the screw—tightening is what ensures that everything stays firm and stable. What are the best tools for installing shelves when it comes to ensuring a strong hold? The screwdriver provides the necessary torque to secure the screws, preventing them from loosening over time.

Without this tool, your shelf would not be properly fastened. A loose screw could cause the shelf to tilt or even fall, damaging your wall or the items on the shelf. Therefore, using the right screwdriver, with enough precision, is essential for a successful installation.

Choosing the Right Screwdriver

Before you begin installing your shelves, it’s important to choose the right screwdriver for the job. What are the best tools for installing shelves in terms of screwdrivers? There are two primary types of screwdrivers you can use: manual and electric.

Manual Screwdrivers: Simplicity and Control

A manual screwdriver is the most basic form of the tool. It comes in various sizes and shapes, including flathead and Phillips. A flathead screwdriver has a single flat blade, while a Phillips screwdriver has a cross-shaped head. Depending on the type of screws you’re using for your shelf installation, you’ll need to select the correct screwdriver head.

Manual screwdrivers offer precision and control. This makes them ideal for delicate work, especially when you need to prevent over-tightening or damaging the surface. They are also great for smaller installations where speed is not a priority. Using a manual screwdriver can provide a satisfying sense of control over your work. However, it might be slower if you’re working on larger projects or have multiple screws to tighten.

Electric Screwdrivers: Speed and Efficiency

For larger installation projects or when you’re installing multiple shelves, an electric screwdriver is highly effective. What are the best tools for installing shelves when you’re looking for speed and efficiency? An electric screwdriver can save you a lot of time. With the press of a button, you can quickly drive screws into place, tightening them securely.

Electric screwdrivers come in many forms, from battery-powered models to corded versions. Battery-powered screwdrivers are particularly convenient, as they offer portability without the need to worry about plugging into a socket. However, it is important to ensure that the battery is fully charged before starting your installation.

Although electric screwdrivers are faster, they require careful handling. You may need to adjust the torque settings to prevent over-tightening, which can damage the screw or the wall.

Tips for Effective Use of a Screwdriver

Once you’ve selected the right screwdriver for the job, it’s time to put it to work. What are the best tools for installing shelves when you’re using a screwdriver? Here are a few tips to make sure you’re using it effectively.

Tip #1: Apply Steady Pressure

When tightening screws, it’s important to apply consistent, steady pressure. If you apply pressure unevenly, you could strip the screw or damage the material you’re working with. This is especially important if you’re working with softer materials like drywall. A firm grip on the screwdriver will help you maintain even pressure as you tighten each screw.

Tip #2: Use the Right Size Bit

Make sure the bit you are using matches the type and size of the screw head. What are the best tools for installing shelves in terms of choosing the correct screwdriver bit? If the bit is too small, it will slip out of the screw head, causing frustration and potentially damaging the screw. On the other hand, if the bit is too large, it could cause the screw head to become stripped. The correct size ensures a secure fit and easier tightening.

Tip #3: Tighten Gradually

It’s important to tighten the screw gradually. Tighten it a little bit at a time, alternating between screws if you are installing multiple shelf brackets. What are the best tools for installing shelves when you want to avoid damaging your wall? Tightening too quickly can cause uneven pressure, leading to misaligned brackets. By tightening the screws in small increments, you can ensure that each one is firmly secured before moving on to the next.

Using a Screwdriver for Different Types of Walls

The type of wall material you’re working with can affect how you use your screwdriver. What are the best tools for installing shelves depending on the wall material? Let’s explore how to approach different types of walls.

Drywall and Plaster

Drywall is the most common type of material for modern interiors. If you are installing shelves on drywall, you may need to use wall anchors in addition to screws. The anchors provide extra support and prevent the screws from pulling out. When using a screwdriver on drywall, apply consistent pressure but avoid over-tightening. The material can crack if you apply too much force.

For plaster walls, a screwdriver can be used similarly. However, you may need to drill a pilot hole before inserting the screws. Plaster tends to be more brittle, so pre-drilling helps prevent cracking.

Wood and Brick

When installing shelves in wood or brick, a screwdriver is still a necessary tool. What are the best tools for installing shelves when working with these stronger materials? For wood, a screwdriver will suffice to tighten screws, but you may want to pre-drill the holes to avoid splitting the wood. For brick or concrete walls, you may need a hammer drill for the initial hole, followed by a screwdriver to tighten the screws or wall anchors.

Importance of Torque Settings

If you’re using an electric screwdriver, adjusting the torque settings is crucial. What are the best tools for installing shelves when considering torque? Torque refers to the amount of twisting force applied to the screw. Too much torque can cause the screw to strip, while too little can lead to a loose fit. Modern electric screwdrivers allow you to set the torque to an appropriate level for the material you’re working with.

Adjusting the torque ensures that the screws are properly tightened without damaging the surface or the screw itself. For soft materials like drywall, lower torque settings are recommended, while for harder materials like wood, a higher setting might be necessary.

Maintaining Your Screwdriver

To get the best performance from your screwdriver, regular maintenance is essential. What are the best tools for installing shelves when it comes to keeping your screwdriver in good condition? Make sure to clean the tool after each use, especially if you’ve worked with dust or debris. Store it in a safe place to avoid damage and check the battery (if using a rechargeable screwdriver) to ensure it’s charged and ready for the next use.

Over time, the screwdriver’s bits may wear down. Make sure to replace them when they start showing signs of wear, such as slipping or stripping screws. Keeping your screwdriver in top condition will save you time and effort on future projects.

Conclusion: The Essential Role of a Screwdriver

In summary, what are the best tools for installing shelves when it comes to securing your shelves? A screwdriver is essential. Whether you choose a manual or electric model, this tool helps you achieve a secure, tight fit for your screws, ensuring your shelves remain safe and stable over time.

By following the tips and techniques outlined in this section, you’ll be able to use your screwdriver efficiently and effectively. Whether you’re tightening screws in drywall, wood, or brick, understanding how to properly use this tool is crucial for any shelf installation project.

Tool #6: Stud Finder – For Wall Stability

When you are installing shelves, one of the most important considerations is how to ensure the stability of your shelves. The stud finder is a tool that can make a significant difference in how securely your shelf is mounted to the wall. In this section, we’ll explore what a stud finder is, why it’s essential, and how to use it effectively during your installation process.

What is a Stud Finder

A stud finder is a device used to locate studs behind the wall. A stud is the vertical framing element inside a wall that provides structural support. Studs are typically made of wood or metal, and they are spaced evenly within the wall, usually 16 or 24 inches apart. A stud finder helps you locate these studs, which is crucial when installing heavy objects like shelves.

Without a stud finder, finding the right spot to anchor your shelves becomes much harder. If you fail to mount the shelf directly into a stud, the weight of the shelf could pull it off the wall, causing damage or injury. The stud finder ensures you mount your shelves securely, preventing potential accidents.

Why You Need a Stud Finder for Shelf Installation

Stud finders are essential for wall stability when installing shelves. Without them, you may end up anchoring your shelf into drywall alone, which is not strong enough to hold the weight. Drywall can easily break or tear under pressure, especially when it’s supporting something heavy like books or display items. To avoid this, you need to anchor the shelf brackets into the studs.

The stud finder simplifies this process. It helps you pinpoint the exact location of the studs behind the wall. By securing your shelf brackets into these studs, you ensure that the shelf has a stable base, which will prevent any wobbling or sagging. This is especially important for large shelves or shelves that will hold heavy items.

How Does a Stud Finder Work

Understanding how a stud finder works can help you use it more effectively. Stud finders use different technologies to locate studs behind the wall. There are mainly two types of stud finders: electronic and magnetic.

Electronic Stud Finders

Electronic stud finders are the most common and work by detecting changes in wall density. When you move the stud finder across the wall, it sends out a signal. If the signal encounters a denser material, like a stud, the stud finder will alert you by lighting up or making a sound. Electronic stud finders can also help you locate the edges of the stud, making it easier to align your shelf brackets.

Magnetic Stud Finders

Magnetic stud finders work by detecting the metal nails or screws used to attach the drywall to the studs. They are simpler and cheaper than electronic models. However, they may not be as accurate as electronic stud finders. Magnetic stud finders are a good option for quick installations, but if you need more precision, an electronic model is recommended.

How to Use a Stud Finder

Using a stud finder is straightforward, but it requires a little practice to master. Below is a step-by-step guide to using a stud finder effectively.

Turn On the Stud Finder

Start by turning on the stud finder. Make sure the batteries are fresh or fully charged. If your stud finder has a calibration function, use it to calibrate the device before starting.

Place the Stud Finder on the Wall

Hold the stud finder flat against the wall where you want to install the shelf. Start at one end of the area where you plan to mount your shelf.

Move the Stud Finder Slowly Across the Wall

Slowly slide the stud finder horizontally across the wall. Keep it in constant contact with the wall, and move it at a steady pace. The stud finder will beep or light up when it detects a stud.

Mark the Spot

When the stud finder detects a stud, mark the spot with a pencil. It’s a good idea to mark the center of the stud, as this is where you’ll anchor the shelf brackets. Most stud finders also indicate the edges of the stud, which can help you identify the exact center.

Double-Check the Reading

It’s always a good idea to double-check your reading. Move the stud finder a few inches to the left or right and repeat the process. This will help confirm the student’s position.

Find the Other Side of the Stud

After locating one side of the stud, you should find the other side to determine the width. This will help you place the shelf bracket at the optimal location.

Common Problems When Using a Stud Finder

Although stud finders are designed to make the process of locating studs easier, there are a few challenges you might face. Here are some common issues and how to solve them.

Inaccurate Readings

If your stud finder is giving inaccurate readings, make sure it’s calibrated correctly. Also, ensure that you’re using it on the right surface. Stud finders work best on drywall, but they may struggle with thicker or more solid materials like plaster or concrete. If this is the case, you may need a more advanced model designed for thicker walls.

False Positives

Sometimes, a stud finder might indicate that a stud is present when it’s not. This can happen if the device detects other materials like pipes, wires, or nails that are embedded in the wall. To avoid false positives, carefully check the location where the stud finder indicates a stud. You can use a small nail or screw to test the area before drilling into it.

Difficulty Detecting Studs

Some stud finders struggle to detect studs behind thick or uneven walls. If you find that your stud finder is not working properly, try moving it in different directions. Also, ensure that your wall is not covered by wallpaper, paint, or other layers that might block the signal.

Types of Stud Finders

As mentioned earlier, there are two primary types of stud finders: electronic and magnetic. Let’s take a closer look at each.

Electronic Stud Finders

These are the most accurate and versatile options available. They can detect studs deeper inside the wall, making them ideal for thicker walls or walls with insulation. Electronic stud finders are also designed to detect live wires, which adds an extra layer of safety when you’re drilling into the wall. However, they are more expensive than magnetic stud finders and require batteries or charging.

Magnetic Stud Finders

Magnetic stud finders are more affordable and simpler to use. They are best for quick jobs and can easily detect the nails or screws used to attach the drywall to the studs. They are compact and lightweight, making them easy to carry around. However, they may not detect studs as accurately as electronic stud finders, especially if the nails are not easily detectable.

Conclusion: Why the Stud Finder is Essential for Shelf Installation

In conclusion, a stud finder is an invaluable tool for ensuring that your shelf installation is stable and secure. It helps you locate the studs behind the wall, which is critical for anchoring your shelf brackets properly. Without it, you risk attaching your shelves to drywall, which is not strong enough to support heavy loads.

Using a stud finder will make your installation process smoother, safer, and more reliable. Whether you’re installing a simple floating shelf or a heavy-duty display unit, the stud finder will ensure that your shelves stay in place.

Tool #7: Pencil – For Marking the Spots

When it comes to installing shelves, a small but crucial tool is often overlooked: the pencil. A pencil may seem basic, but it plays an essential role in ensuring that your shelf installation is precise and secure. In this section, we will explore the importance of the pencil for marking spots, how to use it effectively, and why it’s indispensable for achieving accurate shelf placement.

Why Marking the Wall is Important

Before you drill holes or secure any brackets to the wall, marking the spots where you will place the screws is crucial. Without this, you risk misaligning the shelves or drilling in the wrong places, which could lead to crooked shelves or damage to your wall. A pencil provides a simple and effective way to make these marks without causing permanent damage to the surface.

The pencil marks serve as a guide throughout the installation process. Whether you’re securing brackets into studs or marking where screws should go, these guides ensure everything is aligned correctly. The pencil also helps you measure, position, and ensure the shelf will be installed at the desired height and angle.

The Different Types of Pencils for Marking

When selecting a pencil for marking, not all pencils are created equal. The type of pencil you choose will affect the clarity of your markings and how easy it is to remove them later. Here’s a look at the most common types of pencils used for marking during installation.

Regular Wooden Pencils

A regular wooden pencil is the most common and widely available option. It is versatile and can be sharpened to a fine point for precise markings. However, the markings left by wooden pencils can sometimes be smudged, especially if you are working in a high-traffic area or if you accidentally touch the marks with your hands.

Wooden pencils are generally great for marking drywall, wood, and plaster surfaces. They are easy to control and provide clear, visible lines. Just make sure you sharpen the pencil regularly to maintain precision.

Mechanical Pencils

Mechanical pencils are another option that can be highly effective for marking. These pencils use a refillable lead that can be advanced with a simple click. Mechanical pencils provide a finer, sharper line than regular wooden pencils, making them an excellent choice for smaller or more intricate measurements.

If you need to make very small, precise marks, a mechanical pencil is a great tool. It’s particularly useful when you need to mark the exact location of screws or small mounting holes. Some mechanical pencils even come with erasable leads, making it easy to remove the marks once the installation is complete.

Carpenter’s Pencils

Carpenter’s pencils are flat, wide pencils designed for use in construction and installation work. Their flat design makes them easy to hold and more stable on uneven surfaces, and they can leave a darker, more visible mark. Carpenter’s pencils are ideal for marking on rough surfaces, such as wood, plywood, or plasterboard.

If you’re working with materials that are difficult to mark with a regular pencil, a carpenter’s pencil might be the right choice. Their broad lead also makes them suitable for marking studs and larger areas.

How to Mark the Wall Accurately

Marking the spots on the wall is a precise task that requires careful attention to detail. A pencil allows you to make small, clear marks without damaging the surface. Let’s take a look at how to use a pencil to mark spots effectively during shelf installation.

Step 1: Measure the Position

Before you start marking, you need to measure the position of your shelf. Determine the height where you want your shelf to be placed. Use a measuring tape or ruler to find the correct spot and ensure that it’s level.

Once you’ve found the height, use a pencil to make a small mark at the top and bottom of where your shelf will go. This ensures that the shelf will be positioned evenly on the wall.

Step 2: Mark the Center of the Brackets

The next step is to mark the positions of the brackets. Depending on the type of shelf, you may need to install one or more brackets. Use the pencil to mark the center of where each bracket will be attached to the wall. This is a critical step, as it will help you align the brackets correctly.

Make sure to double-check your measurements to ensure that the brackets are evenly spaced. You can use a level or measuring tape to verify that the marks are in the right spots.

Step 3: Mark the Screw Placement

After marking the bracket centers, you’ll need to mark where the screws will go. A pencil helps you position the screws at the exact location where they’ll secure the brackets to the wall.

For this step, hold the bracket in place on the wall, making sure it’s level. Once the bracket is in position, use a pencil to mark the screw holes. This ensures that you drill in the right places, preventing the screws from being placed too high, too low, or too close together.

Step 4: Double-Check Your Marks

After you’ve made the initial marks, take a step back and double-check the alignment. Are the marks even? Are they positioned correctly for the shelf size and bracket placement? It’s always a good idea to remeasure and verify the marks before drilling into the wall. Making adjustments now can save you time and effort later on.

Tips for Accurate Marking

For accurate and reliable marks, here are a few tips to keep in mind when using a pencil for shelf installation.

Use a Level for Straight Lines

To ensure that your marks are level, use a spirit level. Place the level along the wall to make sure your pencil marks are aligned horizontally or vertically, depending on how your shelf will be installed. This helps prevent crooked shelves and ensures that your shelf will be straight once installed.

Use a Laser Level for Precision

For even greater accuracy, consider using a laser level. Laser levels project a visible straight line across the wall, giving you a guide for marking your shelf placement. This is especially helpful if you need to install multiple shelves and want them to be perfectly aligned.

Use a Straight Edge for Long Markings

If your shelf is long or spans across a larger area, use a straight edge or ruler to mark along the wall. This ensures that your pencil marks are continuous and perfectly straight. A long, straight edge is especially helpful when marking multiple screw placements along the length of the shelf.

Why a Pencil is the Best Tool for Marking

While there are other options available for marking, a pencil is the best tool for the job when it comes to shelf installation. Here’s why:

Easy to Erase: Unlike markers or pens, pencil marks can be easily erased if they are not in the correct position. You can use an eraser to remove any mistakes without leaving permanent marks on the wall.

Precision: Pencils provide precise, sharp lines that are easy to follow. This is especially important when you’re making small marks for screws or brackets.

Non-Damaging: Unlike chalk or paint, pencil marks are gentle on the wall surface and will not cause damage. Once you’ve installed your shelf, you can simply wipe away any leftover pencil marks.

Visibility: Pencil marks are dark enough to be seen easily but light enough to be erased without leaving a trace.

Conclusion: The Essential Role of the Pencil in Shelf Installation

In conclusion, while it might seem like a simple tool, the pencil plays an essential role in ensuring the success of your shelf installation. It allows you to mark your wall accurately, ensuring that your shelves are installed at the right height and in the right place. By marking the positions of the brackets, screws, and studs, you make the entire installation process much easier and more precise.

The pencil helps prevent costly mistakes, saving you time and effort in the long run. It ensures that your shelves are mounted securely, and everything is aligned as it should be. Whether you’re a seasoned DIYer or a beginner, don’t underestimate the power of a pencil when installing shelves.

Tool #8: Shelf Brackets – For Support

When it comes to installing shelves, the shelf brackets you choose are just as important as the tools you use. These small, yet mighty components, play a critical role in ensuring your shelves are properly supported and stable. In this section, I’ll walk you through the different types of shelf brackets, why they matter, how to choose the right ones, and how to install them for maximum support.

Why Are Shelf Brackets Important

Shelf brackets are the unsung heroes of the shelving world. Without them, shelves would lack the necessary support to hold anything securely. Shelf brackets serve as the foundation for your shelves, carrying the weight of whatever you place on them. Whether you’re using them for a few books or a display of delicate items, the right brackets ensure that your shelves remain steady and functional.

When you install shelves, the weight of the items placed on them puts pressure on the brackets. Over time, weak or poorly chosen brackets can lead to sagging, tilting, or even failure. This is why it’s essential to select shelf brackets designed to carry the load you’re planning to place on the shelf.

Types of Shelf Brackets

There are many different types of shelf brackets, and each is suited for specific applications. Understanding the differences will help you make the right choice for your project.

L-Brackets

L-brackets are one of the most commonly used types of shelf brackets. They are shaped like the letter “L,” and they are perfect for supporting shelves against a wall. L-brackets are designed to sit under the shelf and provide vertical and horizontal support. They are ideal for heavier loads and for shelves that are mounted directly to the wall. L-brackets come in various sizes and materials, from light-duty models for small shelves to heavy-duty ones that can hold large items like books or electronics.

Floating Brackets

Floating brackets are a sleek and modern choice. Unlike traditional brackets, they are hidden behind the shelf, creating a “floating” effect. These brackets are often used in contemporary interior designs, where the focus is on clean lines and minimalism. Floating brackets are typically made of steel or other durable materials, and they work by attaching directly to the wall. They are great for smaller shelves, but may not offer enough support for very heavy loads.

Heavy-Duty Brackets

If you’re installing a shelf that needs to hold a significant amount of weight, heavy-duty brackets are the best choice. These brackets are often larger and made from stronger materials like steel or iron. Heavy-duty brackets are designed to withstand the pressure of large or dense objects. They are especially important for shelves in kitchens, garages, or any area where the shelf will hold tools, equipment, or heavy decorative items.

Decorative Brackets

While functionality is key, aesthetic appeal is also important in many home installations. Decorative brackets offer both form and function. These brackets are often made of cast iron, brass, or wood and come in a variety of styles, from ornate to minimalist. Decorative brackets are ideal for showcasing lighter items or adding a touch of style to your shelf installation.

Adjustable Brackets

If you want flexibility in your shelf design, adjustable brackets are a good option. These brackets allow you to change the height of the shelf after installation. They are often used in environments where shelves need to be moved or repositioned over time, such as in warehouses or offices. Adjustable brackets typically have sliding mechanisms or multiple settings, giving you the ability to customize the position of the shelf as needed.

How to Choose the Right Shelf Bracket

Choosing the right shelf bracket is crucial to ensuring that your shelf remains secure. Here are the key factors to consider when selecting the appropriate bracket for your project.

1. Weight Capacity

The most important factor in choosing shelf brackets is weight capacity. You need to consider what you will be placing on the shelf and ensure that the brackets can handle the load. For example, if you’re installing a shelf to hold books, you’ll need a bracket that can support the weight of multiple books, which can be quite heavy. On the other hand, if you’re installing a shelf for decorative items, you may not need as much support.

To determine the weight capacity of the brackets, check the manufacturer’s guidelines. They should provide details on the maximum weight the brackets can support. Always opt for a bracket that offers a higher weight capacity than you think you need to avoid overloading.

2. Material

The material of the bracket plays a significant role in both its strength and appearance. Common materials for shelf brackets include:

Steel: Steel brackets are strong and durable, making them a good choice for heavy-duty installations. They are resistant to wear and tear and are perfect for holding up heavy items.

Wood: Wooden brackets are often used for decorative purposes. While they may not be as strong as metal brackets, they add a warm and rustic aesthetic to the installation.

Aluminum: Aluminum brackets are lightweight and corrosion-resistant. They are often used for smaller shelves or in areas where rust may be a concern, such as bathrooms or outdoor spaces.

Iron: Cast iron brackets are another popular option, particularly for heavy-duty shelves. These brackets are robust and can withstand a lot of pressure, but they are also more expensive and can be heavier.

3. Shelf Size

The size of your shelf will determine the size of the brackets you need. Larger shelves, such as those that span a wider area, will need larger brackets to support the weight. Small, narrow shelves can be supported by smaller, lighter brackets. Make sure the brackets you choose are proportionate to the size of the shelf to ensure stability.

4. Style

If the appearance of the brackets matters to you, then consider the style. If you’re installing shelves in a space where the brackets will be visible, you might prefer decorative or floating brackets for a sleek, minimalist look. For more utilitarian spaces like garages or storage areas, standard L-brackets or heavy-duty brackets may be more appropriate.

Installing Shelf Brackets

Now that you’ve chosen the right shelf brackets, it’s time to install them. Installing the brackets correctly is essential for ensuring your shelves are stable and secure. Here is a step-by-step guide to installing shelf brackets:

Step 1: Measure and Mark

Before you start drilling, use a measuring tape to mark where the brackets will go. Make sure the spacing between the brackets is even. It’s also important to measure the height at which you want the shelf to sit. Once you have the measurements, mark the spots on the wall where you’ll drill the holes.

Step 2: Drill Pilot Holes

Use a drill to create pilot holes in the wall at the marked spots. Make sure the drill bit is appropriate for the type of wall material (drywall, concrete, etc.). If you’re drilling into drywall, be sure to use wall anchors to ensure the brackets are secure. For masonry walls, you may need a masonry bit and wall plugs to hold the brackets in place.

Step 3: Attach the Brackets

Once the holes are drilled, attach the shelf brackets to the wall using screws. If you’re installing heavy-duty brackets, use longer, stronger screws to ensure a secure fit. Make sure the brackets are level as you screw them into place.

Step 4: Install the Shelf

Once the brackets are secured, place the shelf on top of the brackets. If the shelf is adjustable, adjust the height as needed. For non-floating shelves, make sure the shelf fits snugly onto the brackets and that the brackets are positioned correctly to support the weight of the shelf and its contents.

Step 5: Check for Stability

Finally, check the stability of the shelf. Give it a gentle shake to ensure that it is firmly in place. If there’s any wobbling or movement, double-check the screws and make sure the brackets are properly aligned.

Conclusion: The Importance of Shelf Brackets

In conclusion, shelf brackets are essential for supporting your shelves and ensuring they stay stable and secure. Choosing the right brackets depends on the weight of the items you plan to place on the shelf, the material of the brackets, and the overall design you’re aiming for. By selecting the right type of brackets and installing them properly, you can ensure that your shelves will serve you for years to come.

Remember, the brackets are just as important as the shelf itself. Whether you’re installing a small decorative shelf or a large, heavy-duty storage unit, the right bracket makes all the difference. With the right support, your shelves will remain secure, functional, and safe.

Tool #9: Hammer – For Tapping in Anchors

When you’re installing shelves, one of the most important tools you’ll need is a hammer. A hammer is often overlooked, but it plays a crucial role in the installation process. Specifically, it helps with tapping in anchors, which are essential for securing your shelves to the wall. This section will explore why a hammer is necessary, how to use it correctly, and some common mistakes to avoid.

What Is a Hammer

A hammer is a simple tool that consists of a heavy “head” attached to a long handle. The hammer’s head is usually made of metal, and its flat side is used for striking. While a hammer may seem like a basic tool, it is incredibly versatile and essential for a wide range of tasks, including installing anchors for shelves.

When installing shelves, you will often need to insert anchors into the wall to hold the screws that secure your shelf brackets. This is where the hammer comes in. By using the hammer to gently tap in the anchors, you ensure that they are securely placed and won’t move during installation.

Why a Hammer Is Essential for Installing Anchors

Using a hammer to tap in anchors might seem simple, but it’s important for several reasons. The first reason is precision. When installing shelves, the anchors must be positioned properly. A hammer allows you to apply the right amount of force without damaging the wall or the anchors themselves.

Another reason why a hammer is necessary is to prevent slippage. When you’re inserting an anchor, especially one that’s designed to expand when the screw is tightened, the hammer ensures that the anchor fits snugly into the hole. This prevents the anchor from slipping out or misaligning, which can cause the shelf to become unstable.

Additionally, a hammer allows you to control the depth at which the anchor is inserted. Over-tapping or under-tapping the anchor could lead to problems when securing the shelf brackets later on. By using a hammer, you can adjust the depth and ensure that the anchor is perfectly positioned.

Types of Anchors You May Need to Tap In

There are several types of anchors you may encounter when installing shelves. Each type has its own specific requirements for installation. Some anchors require a light tap, while others need more force. Here are a few common types of anchors and how the hammer is used with each.

Plastic Expansion Anchors

Plastic expansion anchors are commonly used for lightweight shelves. They are easy to install and require a gentle tap with a hammer. These anchors expand when the screw is inserted, creating a tight grip in the wall. The hammer is used to tap the anchor into the wall until it’s flush with the surface. It’s important not to over-tap these anchors, as doing so can cause them to crack or deform.

Toggle Bolts

Toggle bolts are used for heavier shelves and are ideal for hollow walls, such as drywall or plasterboard. These anchors consist of a bolt with a spring-loaded mechanism that opens up once it passes through the wall. The hammer is used to insert the toggle into the wall and to push the spring-loaded mechanism in place. Once the toggle is in position, the screw is tightened to secure the shelf.

Molly Bolts

Molly bolts are designed for medium to heavy-duty shelving. They are similar to toggle bolts but feature a sleeve that expands when the screw is tightened. Molly bolts are commonly used in drywall and other soft materials. The hammer is used to insert the bolt and expand the sleeve to create a secure anchor. Like plastic expansion anchors, it’s important not to over-tap molly bolts, as they can become damaged.

Wall Plugs

Wall plugs are often used for heavier shelves or objects. These anchors are inserted into pre-drilled holes in the wall and require a firm tap with a hammer to ensure they fit snugly. Once in place, the screw is inserted to expand the plug, which creates a tight, secure fit. A hammer helps achieve the right amount of force to insert the wall plug without damaging it.

How to Use a Hammer Correctly for Tapping in Anchors

Using a hammer to tap in anchors requires a steady hand and the right technique. Here’s a step-by-step guide to ensure that you use the hammer effectively:

Choose the Right Hammer

Not all hammers are created equal. For tapping in anchors, a standard claw hammer or a rubber mallet works best. A claw hammer is ideal for general use, while a rubber mallet is better for softer materials or when you need a gentler touch. If you’re working with delicate surfaces, a rubber mallet will reduce the risk of damage.

Align the Anchor

Before tapping the anchor into the wall, make sure it is aligned with the hole you drilled. Double-check the positioning and ensure that the anchor is centered in the hole. Misalignment can lead to the anchor slipping out of place.

Tap Gently

Once the anchor is aligned, begin tapping it into the hole with a few light taps. Use short, controlled strokes. It’s important to avoid using too much force, as this can cause the anchor to deform or break. Tap gently until the anchor is flush with the wall’s surface.

Check the Anchor’s Position

After tapping the anchor in, check that it is seated correctly. It should be flush with the wall and not protruding out. If the anchor is too deep, it may not expand correctly when the screw is inserted. If it’s too shallow, the screw won’t hold securely.

Adjust the Depth If Necessary

If the anchor is not seated properly, you can adjust it by tapping it in a little more. However, be cautious not to over-tap, as this could damage the anchor or wall. If the anchor is too deep, you may need to remove it and start again with a new anchor.

Common Mistakes When Using a Hammer to Tap in Anchors

Using a hammer to tap in anchors seems like a simple task, but there are a few common mistakes that can lead to problems. Here are some mistakes to watch out for:

Over-Tapping the Anchor

One of the most common mistakes is over-tapping the anchor. This happens when you hit the anchor too hard or too many times, causing it to become damaged or pushed too deep into the wall. Over-tapping can make the anchor ineffective, as it won’t expand properly when the screw is inserted.

Under-Tapping the Anchor

On the flip side, under-tapping the anchor can also cause problems. If the anchor is not tapped in enough, it may not fit snugly in the hole. This can result in the anchor moving or slipping out of place when the screw is inserted. Always make sure the anchor is seated firmly but not overdone.

Using the Wrong Hammer

Choosing the wrong hammer for the job can lead to damage. A hammer that is too heavy can cause unnecessary force, while a hammer that is too light may not provide enough power to insert the anchor correctly. Always use a hammer that is appropriate for the type of anchor you are using.

Conclusion: Tapping in Anchors with a Hammer for a Secure Shelf Installation

In conclusion, the hammer is an essential tool for tapping in anchors when installing shelves. Whether you’re using plastic expansion anchors, toggle bolts, or wall plugs, the hammer ensures that the anchors are properly inserted and secured. By using the hammer correctly, you can ensure a stable and secure shelf installation. Remember, tapping in anchors requires precision, so be sure to use gentle, controlled strokes and avoid over-tapping or under-tapping the anchor.

By mastering the use of the hammer, you’ll be able to install shelves with confidence, knowing that the anchors are securely in place and your shelf will hold up over time.

Conclusion: Choosing the Right Tools for the Job

As we’ve discussed throughout this guide, selecting the right tools is crucial for installing shelves correctly. The tools you choose will directly impact the stability, safety, and aesthetics of your shelf installation. In this conclusion, we’ll review the key tools we’ve covered and why each one is necessary. Choosing the right tools ensures that your shelf installation is both efficient and durable.

The Importance of Preparation

Before starting any shelf installation project, preparation is key. Understanding the tools you need and how to use them correctly will save you time and effort. A good tool setup not only makes the job easier but also minimizes mistakes. Having a proper toolkit can eliminate frustration and provide the confidence needed for a successful installation.

One of the first tools you should gather is a stud finder. This device will help you locate the studs behind your walls, which is crucial for installing shelves securely. Without a stud, your shelves won’t be stable, especially if you plan to store heavy items. Using a stud finder ensures that you’re mounting your shelves in the right spot for maximum stability.

The Right Tools for Every Task

Each tool in your installation kit serves a specific purpose. A drill is essential for creating the necessary holes for shelf brackets. Without it, you would struggle to make precise holes in the wall. The level is just as important. It ensures that your shelves are aligned perfectly, preventing them from slanting. A crooked shelf can ruin the appearance of your space, so using a level is critical.

For mounting the brackets securely, you’ll need screws and wall anchors. The screws hold the brackets in place, while the wall anchors help to distribute the weight evenly across the surface. Both are necessary to ensure your shelves stay put. Without them, your installation could fail, and the shelf could fall.

A measuring tape is also essential. It allows you to determine the correct height and position for your shelves. Measuring correctly means you avoid mistakes, ensuring the shelves look neat and are functional.

The Role of Quality Tools

Not all tools are created equal. Investing in high-quality tools will pay off in the long run. Cheaper tools may get the job done, but they often wear out faster and may not perform as well. High-quality tools, on the other hand, offer greater precision and reliability. For instance, a durable stud finder will give you accurate readings, and a strong drill will make holes with ease, reducing the risk of damaging your walls.

Moreover, quality tools are safer to use. When installing heavy shelves, you want tools that can handle the weight and pressure without breaking or malfunctioning. Investing in good tools ensures your safety throughout the process.

A Smooth and Successful Installation